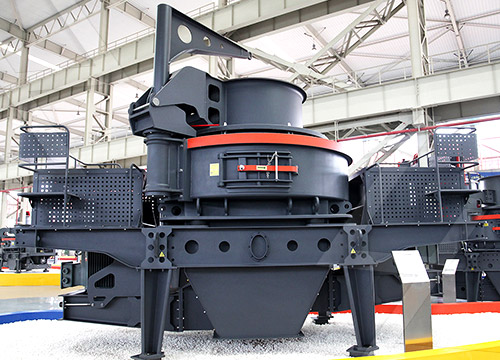

A Quartz Silica Sand Vertical Shaft Impact (VSI) Crusher is a highly efficient machine used in the production of high-quality quartz silica sand, which is widely used in various industries including construction, glass manufacturing, and electronics. The VSI crusher is renowned for its ability to produce fine and uniform particles, enhancing the overall quality of the end product.

Functionality and Design

The primary function of a VSI crusher is to convert large chunks of raw quartz silica into fine particles through a process known as “impact crushing.” The machine features a vertical shaft on which a rotor is mounted. The rotor is equipped with wear-resistant tips that accelerate the material, propelling it against a hard surface to break it down into smaller pieces. This impact force not only crushes the material but also creates a cubical shape, which is often desired in the final product.

The design of a VSI crusher incorporates several key components:

- Feed Hopper: The raw material is fed into the crusher through a hopper, which ensures consistent flow and prevents blockages.

- Rotor: The heart of the VSI crusher, the rotor, spins at high speeds and is responsible for the initial impact that breaks down the material.

- Anvil or Rock Shelf: Positioned around the rotor, this surface provides a hard target for the material to strike, enhancing the crushing process.

- Drive Mechanism: Typically powered by electric motors, the drive mechanism ensures the rotor maintains the necessary speed for effective crushing.

- Discharge Chute: After processing, the crushed material is expelled through a discharge chute, ready for further processing or use.

Benefits

- Efficiency: VSI crushers are known for their high efficiency in producing fine and uniformly sized particles. This is particularly important in industries where the quality and consistency of the material are critical.

- Versatility: These crushers can handle a wide range of materials and produce various grades of sand, making them suitable for different applications.

- Cost-Effectiveness: By reducing the need for additional crushing stages and minimizing waste, VSI crushers help lower operational costs.

- Environmental Impact: Modern VSI crushers are designed to be energy-efficient, reducing their carbon footprint and making them a more sustainable choice for industrial applications.

Applications

- Construction: High-quality silica sand is essential in the production of concrete and asphalt, where it provides strength and durability. VSI crushers ensure the sand meets the stringent specifications required in construction projects.

- Glass Manufacturing: The purity and consistency of silica sand are critical in glass production. VSI crushers help achieve the fine granularity needed for making clear and strong glass products.

- Electronics: Silica sand is a key component in the production of silicon chips used in electronic devices. The precision of VSI crushers ensures the sand is of the required quality.

Maintenance and Safety

Regular maintenance is crucial for the longevity and optimal performance of a VSI crusher. Key maintenance tasks include:

- Inspecting Wear Parts: The rotor tips, anvils, and other wear parts should be regularly checked and replaced as needed to maintain crushing efficiency.

- Lubrication: Proper lubrication of the drive mechanism and bearings is essential to prevent wear and ensure smooth operation.

- Monitoring: Regular monitoring of machine performance can help detect issues early, preventing costly downtime.

Safety is also a paramount concern. Operators should be trained to handle the machinery safely, and appropriate safety measures, such as emergency stop mechanisms and protective guards, should be in place.