In the bustling realm of mining, where raw materials are unearthed, processed, and transformed into valuable commodities, the role of equipment is paramount. Among the crucial machinery, cone crushers stand as stalwart workhorses, indispensable in crushing operations. As mining ventures surge, the demand for robust cone crushers escalates, prompting a dynamic landscape of offerings in the market.

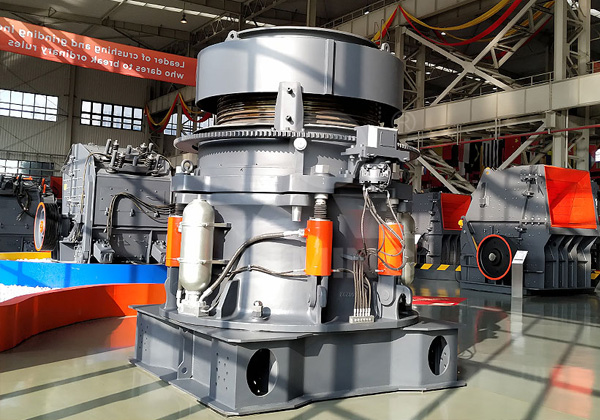

Cone crushers, engineered for heavy-duty applications, epitomize efficiency and reliability in the mining sector. These machines excel in breaking down various materials, from hard rocks to abrasive ores, into finer particles, facilitating downstream processes. Their robust construction and ability to handle diverse materials make them ideal for primary, secondary, and tertiary crushing stages in mining processes.

One of the primary considerations in the purchase of a cone crusher is its design and configuration. Cone crushers come in several types, including standard, short head, and gyratory variants, each tailored for specific crushing tasks. For instance, a standard cone crusher is adept at producing uniform-sized aggregates, while a short head type is preferable for finer crushing. Gyratory cone crushers, on the other hand, offer superior throughput rates, ideal for high-capacity operations.

Furthermore, the choice between stationary and portable cone crushers hinges on operational requirements. Stationary crushers provide stability and high throughput for fixed mining sites, whereas portable variants offer flexibility, catering to mobile operations and temporary setups. The decision must align with the mining project’s duration, scale, and logistical constraints.

Beyond design, the performance metrics of cone crushers play a decisive role in their selection. Key parameters like throughput capacity, power efficiency, and particle size distribution govern operational effectiveness. Modern cone crushers integrate advanced technologies such as hydraulic systems, automation, and variable speed drives to optimize performance and minimize downtime. Prospective buyers should scrutinize these technical specifications to ensure alignment with operational objectives and performance expectations.

In the pursuit of sustainability and operational cost-effectiveness, the energy efficiency of cone crushers emerges as a critical concern. Energy-intensive crushing operations can significantly impact operational expenses and carbon footprints. Thus, cone crushers equipped with energy-efficient features, such as variable frequency drives and optimized crushing chambers, present a compelling proposition for environmentally conscious mining enterprises.

Amidst the myriad of options, buyers must exercise due diligence, considering factors beyond the initial purchase price. Evaluating the vendor’s track record, customer testimonials, and service commitments is indispensable for making informed decisions. Collaborating with reputable suppliers fosters synergistic partnerships, wherein mutual success is predicated on equipment reliability, operational efficiency, and customer satisfaction.

Beyond technical specifications and financial considerations, aftersales support and service play a pivotal role in the buying process. Reliability, prompt maintenance assistance, and availability of spare parts are crucial for ensuring uninterrupted operations. Cone crusher manufacturers differentiate themselves by offering comprehensive support packages, including training, troubleshooting, and onsite assistance.