How to choose the model of the ball mill in the cement plant is mainly based on the grinding needs of the user. The fineness required by the user is different, the production capacity is different, and the model of the ball mill selected is also different, but at the same time, the maximum feed size and particle size of the cement ball mill must be considered. changes, the distribution of grinding media, the hardness of the material, the wet viscosity of the material, etc.

Ball mill production capacity

The production capacity of the ball mill is higher than the design to ensure the output. When the ball mill of the cement plant is designed, the cement ball mill selected should be able to adapt to the hardening or thinning of the ore in the depth of the deposit, and at the same time ensure the smooth production in the initial stage, but the plan generally does not change quickly. Therefore, when we choose ball mill equipment for cement plants, we try to choose ball mills with larger capacity than expected to ensure production.

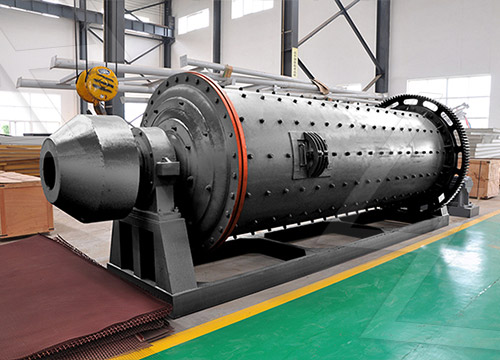

Large-scale ball mill

Appropriately consider the large-scale equipment and select equipment with high operation rate. Large-scale ball mills in cement plants are the general trend in design. With the popularization of large-scale equipment, the corresponding technical operation and equipment management requirements are also improved. Large-scale equipment can increase cement production The operation efficiency of the ball mill in the factory, and the large-scale equipment can improve the operation rate of the equipment, while the ball mill in the cement plant with high operation rate corresponds to less maintenance time, and the overall situation is better.