Aggregate quarry crushing equipment plays a crucial role in the process of turning large rocks into small, uniform pieces. These pieces, known as aggregates, are essential components in the construction industry, used in the production of concrete, asphalt, and various types of road base materials. The efficiency and effectiveness of aggregate crushing equipment directly impact the quality and cost of construction projects.

One of the primary pieces of equipment in aggregate quarry crushing is the jaw crusher. This robust machine is designed to break down large rocks into smaller, more manageable sizes. The jaw crusher uses a set of jaws, one fixed and the other moving, to apply pressure and crush the rocks. It is an essential tool in the first stage of the crushing process, reducing the raw material to a size suitable for further processing.

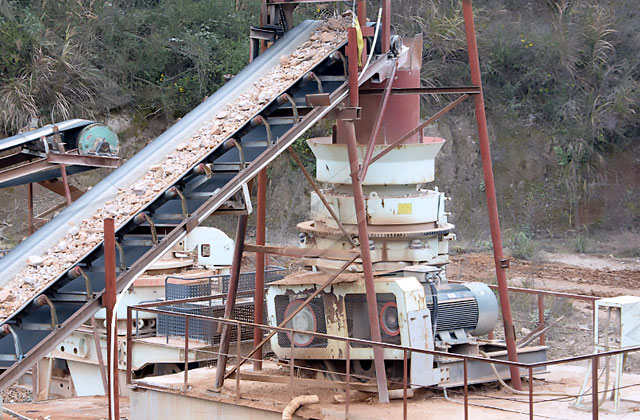

Cone crushers are another critical component in aggregate crushing. They operate by squeezing the material between an eccentrically gyrating spindle and a concave hopper. This action produces a fine, consistent product size. Cone crushers are particularly useful for producing well-shaped and cubical aggregates, which are highly desirable in construction applications.

Impact crushers are versatile machines used in aggregate quarry crushing to break down various types of rock. They work by delivering a powerful impact force that causes the material to break along its natural fractures. Impact crushers are effective for producing high-quality aggregates with good shape characteristics. They are often used in the secondary or tertiary stages of crushing.

Vibrating screens are essential in the aggregate production process. These screens are used to separate the crushed materials into different sizes, ensuring that each aggregate product meets the required specifications. Vibrating screens are equipped with multiple decks, allowing for the classification of materials into various grades. This process is vital for achieving the desired product quality and uniformity.

Conveyors play a crucial role in transporting the crushed material from one stage of the crushing process to another. They are used to efficiently move large quantities of aggregates from the primary crusher to the secondary and tertiary crushers, as well as to the screens for sizing. Conveyors are essential for maintaining a continuous flow of material throughout the aggregate production process, optimizing efficiency and reducing downtime.

In addition to these primary pieces of equipment, aggregate quarry crushing often involves the use of specialized machinery such as impact mills and hammer mills, especially in the production of fine aggregates. These machines are designed to further reduce the size of the material to meet specific requirements.

Aggregate quarry crushing equipment is a fundamental part of the construction industry, providing the necessary materials for building infrastructure. The combination of jaw crushers, cone crushers, impact crushers, vibrating screens, and conveyors ensures the efficient production of high-quality aggregates that meet the stringent requirements of modern construction projects. Continuous advancements in technology and sustainable practices contribute to the ongoing improvement of aggregate quarry crushing equipment, supporting the growth and development of the construction industry.