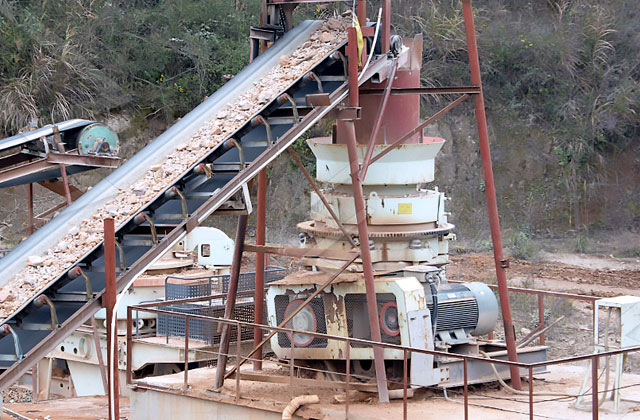

A cone crusher is a vital piece of equipment in the granite quarrying process, playing a crucial role in the efficient and productive extraction of granite. This specialized equipment is particularly well-suited for processing hard and abrasive materials like granite, offering numerous advantages in terms of efficiency, cost-effectiveness, and overall quarry productivity.

One of the primary applications of cone crushers in granite quarries is in the crushing and processing of raw granite blocks extracted from the quarry. These large blocks of granite need to be broken down into smaller, more manageable pieces that can be further processed into various construction materials. The cone crusher excels at this task due to its ability to crush the granite into uniform-sized particles.

The cone crusher operates by compressing the granite between a mantle and a concave, creating a reduction in size that facilitates the production of aggregate materials. The resulting crushed material can be used for a variety of construction applications, including road base, concrete aggregate, and asphalt mix.

Cone crushers offer several advantages in the context of granite quarrying:

- Efficient Crushing Process: Cone crushers are designed to efficiently crush hard and abrasive materials. Their robust construction and high crushing forces make them well-suited for the challenging conditions of granite quarrying.

- Uniform Particle Size: The cone crusher produces uniform-sized particles, ensuring consistent quality in the final crushed material. This is crucial for meeting the specifications required for various construction applications.

- Versatility: Cone crushers are versatile machines that can handle a wide range of materials beyond granite, making them adaptable to different quarrying scenarios. This flexibility is valuable for quarries that may process various types of rock.

- Cost-Effective Operation: While the initial investment in a cone crusher can be significant, the long-term cost benefits are realized through increased efficiency and reduced maintenance costs. The durability of cone crushers contributes to their cost-effective operation over an extended period.

- High Productivity: Cone crushers are known for their high throughput capacity. This is especially important in a granite quarry setting where large volumes of material need to be processed efficiently to meet market demand.

- Automation and Control: Modern cone crushers often come equipped with advanced automation and control systems. These features allow operators to optimize the crusher’s performance, monitor its health, and adjust settings for maximum efficiency.

- Reduced Downtime: Cone crushers are designed for reliable and continuous operation, minimizing downtime in granite quarrying operations. This reliability is crucial for maintaining a steady flow of materials to meet construction project timelines.

The application of cone crushers in granite quarries is integral to the efficient extraction and processing of granite for various construction purposes. Their ability to crush hard and abrasive materials, produce uniform-sized particles, and offer cost-effective, high-productivity solutions makes cone crushers indispensable equipment in the modern granite quarrying industry.