Gypsum is a versatile mineral widely used in various industries, and its processing involves several stages, with crushing being a crucial step in the production process. A reliable gypsum crushing system is essential for efficient and high-quality gypsum processing. Choosing the right supplier for a gypsum crushing system is crucial for ensuring the success of production processes and overall business operations.

One of the key considerations when selecting a gypsum crushing system supplier is the equipment’s efficiency and performance. The crushing system should be designed to handle the specific characteristics of gypsum, such as its hardness, moisture content, and abrasiveness. A reputable supplier will offer crushing equipment that is capable of processing gypsum in various forms, including natural gypsum, synthetic gypsum, and recycled gypsum.

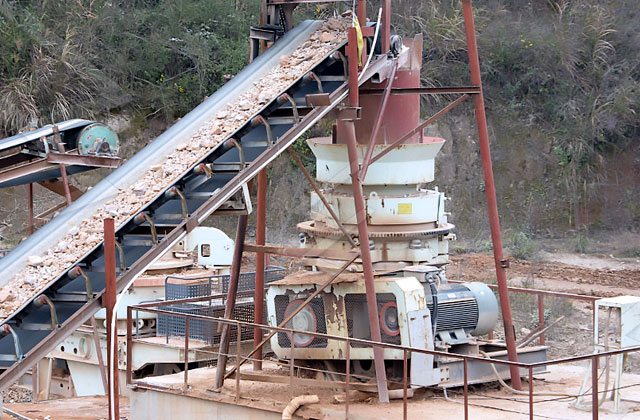

The durability and reliability of the crushing equipment are paramount. Gypsum processing plants operate under demanding conditions, and the crushing system must be robust enough to withstand continuous use. High-quality materials and well-engineered design are essential to ensure the longevity of the equipment and minimize downtime.

In addition to equipment performance, the supplier’s expertise and experience in gypsum processing should be thoroughly evaluated. An experienced supplier understands the unique challenges associated with gypsum crushing and can provide tailored solutions to meet specific production requirements. They should be able to offer comprehensive support, including system design, installation, commissioning, and ongoing maintenance services.

Environmental considerations are increasingly important in modern industrial operations. A responsible gypsum crushing system supplier should offer solutions that prioritize environmental sustainability. This includes dust control measures, noise reduction features, and adherence to relevant environmental regulations. Choosing a supplier with a commitment to eco-friendly practices can contribute to a positive corporate image and regulatory compliance.

Cost-effectiveness is another critical factor in selecting a gypsum crushing system supplier. While it’s essential to invest in high-quality equipment, the overall cost of ownership, including maintenance and operational expenses, should be reasonable. A reputable supplier will provide transparent pricing and help clients understand the long-term value of their investment.

The integration of technology and automation in gypsum crushing systems can enhance efficiency and productivity. A forward-thinking supplier should offer modern solutions that incorporate automation, real-time monitoring, and data analysis to optimize the production process. This not only improves operational efficiency but also allows for better control and management of the entire gypsum processing system.

Customer support and after-sales service are integral components of a successful supplier-client relationship. A reliable supplier should offer prompt and effective support, including troubleshooting, spare parts availability, and ongoing maintenance services. This ensures that any potential issues are addressed quickly, minimizing downtime and disruption to production.