Rock crushing equipment plays a crucial role in various industries, ranging from mining and construction to recycling and aggregates production. As an essential component in the process of breaking down large rocks into smaller, more manageable pieces, crushers are integral to the efficiency and productivity of many operations. In this context, selecting a reliable crusher supplier is paramount to ensuring optimal performance and long-term success.

Types Of Rock Crusher

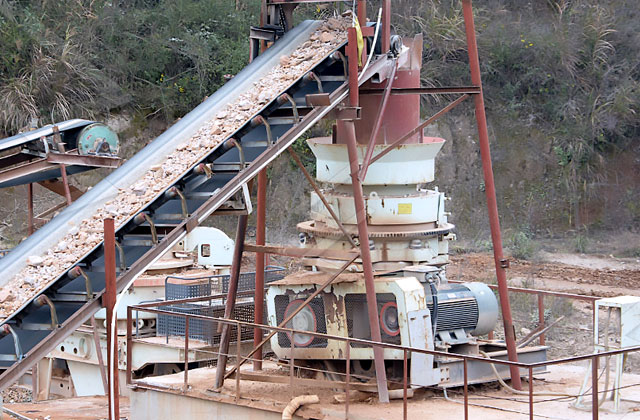

One of the key considerations when choosing a crusher supplier is the type of crusher that best suits the specific needs of the operation. Different crushers are designed for various applications, such as jaw crushers for primary crushing, cone crushers for secondary and tertiary crushing, and impact crushers for shaping and fine-tuning the final product. A reputable supplier should offer a range of crushers to accommodate diverse requirements.

Performance Of Rock Crusher

Durability and reliability are critical factors in the harsh working environments where rock crushing equipment is utilized. A reliable crusher supplier should provide equipment that is robust and built to withstand the demands of heavy-duty operations. High-quality materials, precision engineering, and stringent manufacturing standards are indicative of a supplier’s commitment to delivering durable and dependable crushing equipment.

Efficient performance is another crucial aspect to consider when evaluating crusher suppliers. The capacity of the equipment, the ability to handle different types of materials, and the power consumption are all factors that impact the overall efficiency of the crushing process. A reputable supplier will offer crushers with advanced features and technologies aimed at optimizing performance, reducing downtime, and improving overall operational efficiency.

Maintenance Of Rock Crusher

Maintenance and support services are integral components of a successful rock crushing operation. A reliable crusher supplier should provide comprehensive support, including regular maintenance services, readily available spare parts, and responsive technical support. This ensures that any issues can be addressed promptly, minimizing downtime and maximizing the lifespan of the equipment.

Cost-effectiveness is a fundamental aspect of any equipment procurement decision. While the initial purchase price is an important factor, the total cost of ownership over the equipment’s lifespan must also be considered. A reputable crusher supplier will provide transparent pricing, detailed cost analyses, and help customers make informed decisions based on long-term value rather than just upfront costs.

Selecting the right crusher supplier is a critical decision that directly impacts the success of rock crushing operations. It involves considering factors such as the type of crusher, durability, performance, maintenance and support services, environmental considerations, and cost-effectiveness. By partnering with a reliable and reputable crusher supplier, businesses can ensure that their rock crushing equipment meets their specific needs, operates efficiently, and contributes to the overall success of their operations.