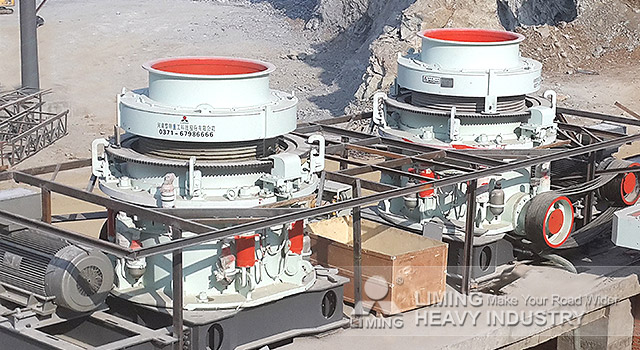

Hard rock processing cone crushers are robust machines designed to handle challenging materials in the mining and aggregates industries. These crushers play a crucial role in the efficient comminution of hard rocks, providing the necessary reduction in size for further processing. In this discussion, we’ll delve into the key features, working principles, and applications of cone crushers in hard rock processing.

Key Features:

- Robust Construction: Hard rock cone crushers are built with robust structures to withstand extreme conditions and heavy-duty applications. High-quality materials and precision engineering ensure durability and long service life.

- Powerful Crushing Mechanism: Cone crushers use a gyrating spindle with an eccentric motion to compress rock against a hardened, wear-resistant concave. This mechanism generates high crushing forces, enabling the efficient reduction of hard and abrasive materials.

- Adjustable Settings: These crushers offer adjustable settings to control the size of the final product. Operators can optimize the crushing process based on the feed material and desired product specifications.

- Hydraulic Systems: Many modern cone crushers incorporate hydraulic systems to provide convenient and efficient adjustments. Hydraulic cylinders facilitate the setting changes and the clearing of the crushing chamber in case of blockages.

Working Principles:

- Crushing Chamber: The hard rock enters the crushing chamber, and as the mantle gyrates around the stationary concave, the material is compressed and crushed between the mantle and concave.

- Eccentric Motion: The eccentric motion of the main shaft causes the mantle to move in a circular path. This movement creates a continuously changing gap between the mantle and concave, effectively crushing the incoming rock.

- Size Reduction: The crushed material exits the crushing chamber at the bottom as the size-reduced product. The degree of reduction depends on factors such as the eccentricity of the spindle, the speed of rotation, and the design of the crushing chamber.

Applications:

- Mining Operations: Cone crushers are widely used in mining operations for the primary and secondary crushing of hard rock ores. They are essential in processing various minerals, including copper, gold, iron ore, and more.

- Aggregates Production: In the construction and aggregates industry, cone crushers play a crucial role in producing high-quality crushed stone for road construction, concrete production, and other applications.

- Quarrying: Hard rock cone crushers are employed in quarrying activities to process large volumes of rock for the production of aggregates used in the construction industry.

- Secondary and Tertiary Crushing: Cone crushers are often used for secondary and tertiary crushing stages in processing plants. They efficiently produce finer-sized materials for further downstream processes.

Hard rock processing cone crushers are integral components in the mining and aggregates industries. Their robust construction, powerful crushing mechanisms, and adjustable settings make them versatile machines for efficiently reducing hard and abrasive materials. These crushers play a vital role in various applications, contributing to the production of high-quality materials for construction and industrial processes.