Limestone quarrying is a significant industry globally, with limestone being a crucial raw material used in various sectors, including construction, agriculture, and manufacturing. Among the key players in this industry are limestone quarry crusher manufacturers, responsible for producing machinery that extracts, processes, and crushes limestone into desired sizes for different applications. This essay delves into the role and importance of limestone quarry crusher manufacturers in the industry.

Limestone quarry crusher manufacturers play a pivotal role in the mining and processing of limestone. Their primary objective is to design, manufacture, and supply high-quality crushers and related equipment tailored to the specific needs of quarry operators. These manufacturers employ advanced technologies and engineering expertise to develop crushers that optimize efficiency, productivity, and safety in limestone quarrying operations.

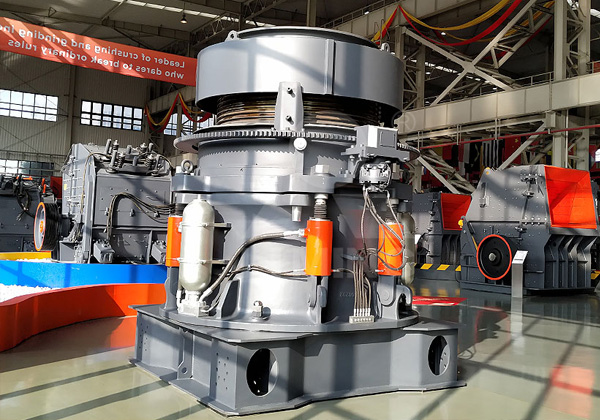

One of the primary functions of limestone quarry crushers is to break down large limestone deposits into smaller, more manageable pieces. This process typically involves the use of heavy-duty crushers capable of handling large volumes of rock. Jaw crushers, gyratory crushers, impact crushers, and cone crushers are among the most commonly used types of crushers in limestone quarrying operations. Each type has its unique advantages, depending on factors such as the size of the limestone deposit, required product specifications, and operational considerations.

In addition to primary crushing, limestone quarry crushers may also be involved in secondary and tertiary crushing stages. Secondary crushers further reduce the size of limestone particles, while tertiary crushers produce even finer aggregates suitable for specific applications, such as concrete production or road construction. Manufacturers design crushers with various features and configurations to meet diverse crushing requirements efficiently.

Furthermore, limestone quarry crusher manufacturers prioritize safety and environmental considerations in their designs. Implementing features such as dust suppression systems, noise reduction measures, and advanced control systems helps minimize the impact of quarrying activities on the surrounding environment and ensure the safety of personnel working in these environments. Additionally, manufacturers may offer solutions for recycling and reusing by-products generated during the crushing process, contributing to sustainable quarrying practices.

Innovations in technology have enabled limestone quarry crusher manufacturers to continuously improve the performance and reliability of their equipment. Automation and remote monitoring capabilities allow for better control and optimization of crusher operations, leading to increased efficiency and reduced downtime. Moreover, advancements in materials and component manufacturing enhance the durability and longevity of crushers, resulting in lower maintenance costs and improved overall lifecycle performance.

Beyond equipment supply, limestone quarry crusher manufacturers often provide comprehensive support services to their customers. This includes technical assistance, maintenance training, spare parts availability, and ongoing customer support to ensure smooth and uninterrupted quarry operations. Building strong relationships with customers and understanding their unique challenges enable manufacturers to deliver tailored solutions that address specific needs effectively.