A cone crusher is a vital piece of machinery used in the production of aggregates, a crucial component in various construction projects ranging from roads to buildings. In this article, we’ll delve into the workings of cone crushers, their importance in aggregate crushing, and their role in the construction industry.

Introduction to Cone Crushers:

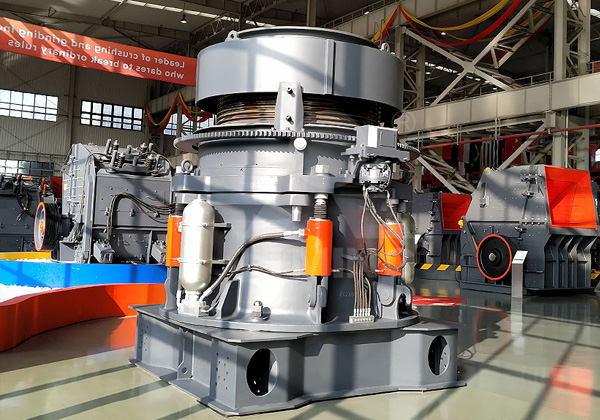

Cone crushers are mechanical devices designed to reduce the size of large rocks into smaller particles. They belong to the family of secondary and tertiary crushers, meaning they operate after primary crushers like jaw crushers or gyratory crushers. Cone crushers utilize a rotating mantle and a concave bowl to crush materials between them. The material is fed into the top of the crusher and is crushed between the mantle and the bowl as it falls downward.

Working Principle:

The working principle of a cone crusher is fairly straightforward. The eccentric shaft rotates, driving the mantle to move in a circular motion around the stationary concave. This motion crushes the material fed into the chamber, resulting in a reduction in size. The adjustable gap between the mantle and concave controls the size of the crushed material.

Importance in Aggregate Crushing:

- Particle Size Reduction: Cone crushers are efficient in reducing large aggregates into smaller sizes, making them suitable for various applications. By controlling the size distribution of the output material, cone crushers ensure the proper gradation required for different construction purposes.

- Uniform Shape and Cubical Particles: Cone crushers produce well-shaped, cubical end products. This uniformity in particle shape is essential for producing high-quality aggregates, as it enhances the workability and strength of concrete mixes.

- Versatility: Cone crushers can handle a wide range of materials, from soft to hard, and from abrasive to non-abrasive. This versatility makes them suitable for crushing different types of aggregates, including limestone, granite, basalt, and more.

- High Productivity: Cone crushers are known for their high productivity levels and efficient operation. With proper maintenance and optimization, they can process large volumes of material quickly, increasing overall production efficiency.

- Reliability and Durability: Modern cone crushers are built to withstand tough operating conditions and heavy-duty applications. They are designed with robust components and durable materials to ensure reliable performance over an extended lifespan.

Role in the Construction Industry:

- Road Construction: Cone crushers play a crucial role in road construction projects by producing aggregates for asphalt and concrete mixes. Properly graded aggregates are essential for ensuring the durability and stability of road surfaces.

- Building Construction: In building construction, cone crushers are used to produce aggregates for various structural components such as concrete blocks, beams, and columns. High-quality aggregates are vital for achieving the desired strength and durability of these structures.

- Railway Ballast: Cone crushers are also utilized in the production of railway ballast, which provides support and stability to railway tracks. Properly sized and shaped aggregates are essential for maintaining the integrity and safety of railway infrastructure.

- Infrastructure Projects: Cone crushers contribute to various infrastructure projects, including bridges, dams, and tunnels, by providing the necessary aggregates for construction materials. These projects rely on high-quality aggregates to ensure the long-term performance and safety of the infrastructure.

In conclusion, cone crushers are indispensable in the aggregate crushing process and play a crucial role in the construction industry. Their ability to produce well-graded aggregates of uniform shape and size makes them essential for various construction applications, ensuring the durability, strength, and stability of infrastructure projects.