Investing in heavy machinery like cone crushers demands careful consideration, especially when evaluating their pricing. Cone crushers are vital in industries like mining, construction, and aggregates, facilitating the crushing of large volumes of materials efficiently. Among the critical factors influencing the pricing of a cone crusher are its capacity, features, brand reputation, and market demand.

Factors Influencing Cone Crusher Pricing

- Capacity: The capacity of the cone crusher is a primary determinant of its price. A higher capacity cone crusher typically commands a higher price due to its ability to process larger volumes of material within a given timeframe.

- Manufacturing Brand: Established brands with a reputation for quality and reliability often price their cone crushers at a premium compared to lesser-known manufacturers. However, opting for a reputable brand ensures better performance and after-sales support, justifying the higher initial investment.

- Technology and Innovation: Cone crushers equipped with advanced technology and innovative features may come with a higher price tag. These features could include automated settings, remote monitoring capabilities, and improved energy efficiency, all of which contribute to enhanced productivity and operational efficiency.

- Power and Efficiency: Cone crushers vary in terms of power requirements and efficiency. Models with higher horsepower motors and superior energy efficiency may have higher upfront costs but offer long-term savings through reduced energy consumption and maintenance expenses.

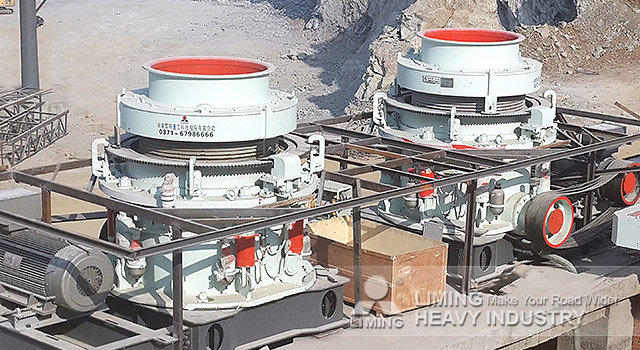

- Size and Configuration: The physical size and configuration of the cone crusher, including the size of the crushing chamber and the dimensions of the machine, can influence pricing. Larger crushers designed for heavy-duty applications typically cost more due to the increased materials and engineering required.

- Optional Features and Accessories: Optional features such as hydraulic adjustment, dust suppression systems, and conveyor extensions can add to the base price of the cone crusher. While these features enhance functionality and operator comfort, they also contribute to overall costs.

- Market Conditions: Market dynamics, including supply and demand fluctuations, currency exchange rates, and geopolitical factors, can impact cone crusher pricing. It’s essential to stay informed about market trends and economic conditions to make strategic purchasing decisions.

- Service and Support: Consideration of after-sales service and support is critical when evaluating cone crusher pricing. Manufacturers offering comprehensive warranties, readily available spare parts, and responsive technical support may justify a higher initial investment.

Determining the Right Price Range

To determine the appropriate price range for a cone crusher with a 350 tons/hour capacity, it’s essential to conduct thorough research and compare offerings from different manufacturers. Consider factors such as your budget, specific operational requirements, and long-term goals when assessing the value proposition of each option.

Investing in a cone crusher with a 350 tons/hour capacity is a significant decision that requires careful consideration of various factors, including pricing. By understanding the key determinants of cone crusher pricing and conducting diligent research, you can make an informed choice that aligns with your operational needs and budgetary constraints. Remember to prioritize quality, reliability, and long-term value when evaluating different options, ensuring optimal performance and return on investment over the equipment’s lifespan.