Aggregate mining crushers play a crucial role in New Zealand’s construction and infrastructure development, facilitating the extraction of raw materials necessary for various projects. From road construction to building foundations, these crushers are pivotal in processing aggregate materials to meet the demands of the construction industry. This article delves into the significance of aggregate mining crushers in New Zealand, exploring their types, operational mechanisms, and their impact on the economy and environment.

Aggregate mining crushers in New Zealand encompass a variety of equipment designed to break down large rocks into smaller, manageable pieces suitable for construction purposes. These crushers are typically categorized into primary, secondary, and tertiary crushers, each serving a distinct purpose in the aggregate production process.

Primary crushers are the initial stage in the crushing process, tasked with reducing the size of raw materials extracted from quarries or mines. They often take the form of jaw crushers or gyratory crushers, capable of handling large rocks with high efficiency. In New Zealand, primary crushers are essential for breaking down the tough volcanic and sedimentary rocks abundant in the country’s landscape.

Secondary crushers follow primary crushers in the processing chain, further refining the crushed material to achieve the desired size and shape. Cone crushers and impact crushers are common types of secondary crushers utilized in New Zealand’s aggregate mining operations. These machines excel at producing uniform-sized aggregates required for construction projects, ensuring structural integrity and quality.

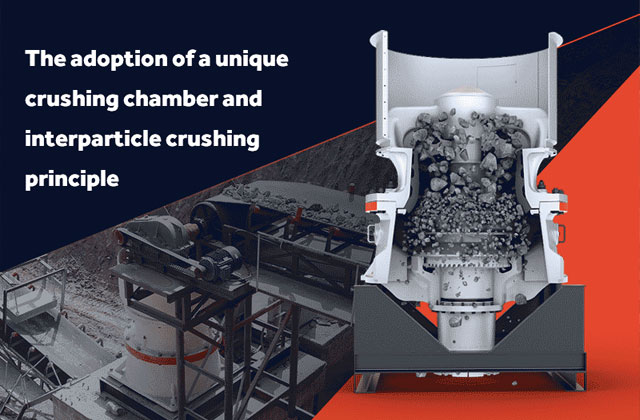

Tertiary crushers play a supplementary role in aggregate production, fine-tuning the output from secondary crushers to meet specific requirements. They are crucial for producing finely crushed aggregates used in asphalt mixes, concrete production, and other specialized applications. Vertical shaft impact (VSI) crushers are widely employed as tertiary crushers in New Zealand, offering precision shaping capabilities for various aggregate products.

The operational efficiency of aggregate mining crushers directly impacts the productivity and profitability of construction projects in New Zealand. Efficient crushers can process large volumes of material swiftly, reducing downtime and operational costs for mining companies. Moreover, they contribute to meeting project deadlines by ensuring a steady supply of high-quality aggregates to construction sites across the country.