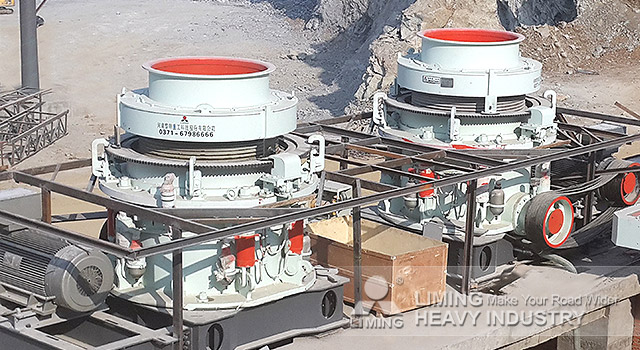

A cone crusher is a vital piece of machinery used in the crushing of various materials, including limestone and granite. This robust equipment plays a crucial role in many industrial and mining operations, offering efficient and reliable performance in reducing large rocks into smaller, more manageable sizes. Let’s delve into the workings of cone crushers, their suitability for processing limestone and granite, and their key features.

Introduction to Cone Crushers:

Cone crushers are commonly used in the mining and aggregate industries for the crushing of hard materials. They operate by compressing the material between a mantle and a concave, creating smaller pieces that are suitable for further processing. Cone crushers come in various sizes and configurations, with different capacities to accommodate different crushing needs.

Suitability for Limestone and Granite:

Limestone and granite are two common types of rocks used in construction, road building, and other industrial applications. Cone crushers are well-suited for processing both materials due to their robust construction and high crushing efficiency.

- Limestone Crushing:

- Limestone is a relatively soft rock compared to granite, but it still requires robust equipment for efficient crushing. Cone crushers excel in crushing limestone due to their ability to crush materials with varying hardness levels.

- Limestone often contains softer materials like clay or silt, which can cause issues in other types of crushers. However, cone crushers can handle such materials effectively, ensuring consistent performance.

- Granite Crushing:

- Granite is a harder and more abrasive rock compared to limestone. It requires heavy-duty machinery capable of withstanding high loads and impact forces. Cone crushers are well-suited for granite crushing due to their durable construction and high crushing capacity.

- The crushing chamber of a cone crusher is designed to withstand the abrasive nature of granite, ensuring minimal wear and tear on the machine’s components.

Key Features of Cone Crushers:

- Crushing Chamber Design:

- Cone crushers feature a specially designed crushing chamber that ensures efficient particle breakage and uniform product size distribution. This design helps optimize the crushing process for different types of materials, including limestone and granite.

- Adjustable Settings:

- Cone crushers offer adjustable settings to control the size of the final product. Operators can easily adjust the gap between the mantle and concave to achieve the desired product size, making cone crushers versatile for various applications.

- High Crushing Efficiency:

- Cone crushers are known for their high crushing efficiency, allowing for the rapid processing of large volumes of material. This efficiency is crucial in industries where productivity and throughput are essential metrics.

- Reliability and Durability:

- Cone crushers are built to withstand harsh operating conditions, making them highly reliable and durable. Their robust construction ensures long-term performance, even in demanding environments such as mining and quarrying.

- Ease of Maintenance:

- Modern cone crushers are designed with ease of maintenance in mind. They feature accessible components and simplified maintenance procedures, reducing downtime and ensuring continuous operation.

In conclusion, cone crushers are highly efficient and reliable machines for crushing hard and abrasive materials like limestone and granite. By understanding the key features and application considerations, you can select the right cone crusher for your specific requirements, ensuring optimal performance, productivity, and product quality in your mining or quarrying operation.