A 500-600 TPH crushing production line is a large-scale production line used for the crushing of limestone, granite, basalt, river stone, and other materials. The production line is designed with several stages of crushing, including primary crushing, secondary crushing, and tertiary crushing. The final product size is usually between 0-5mm, 5-10mm, 10-20mm, 20-30mm, and other specifications.

Components of a 500-600TPH Crushing Production Line

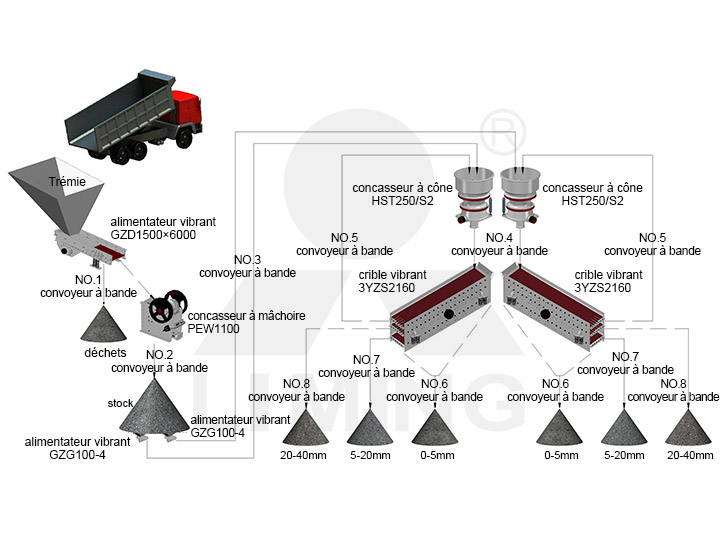

A crushing production line consists of several components, including a vibrating feeder, a jaw crusher, a cone crusher, a vibrating screen, and a belt conveyor. Each component plays a critical role in the crushing process, and they must work together efficiently to achieve the desired results.

The following is an overview of the typical process of a 500-600 TPH crushing production line:

Primary crushing: The raw materials are uniformly fed into the jaw crusher by the vibrating feeder for coarse crushing.

Secondary crushing: After primary crushing, the materials are conveyed to the impact crusher or cone crusher for secondary crushing.

Tertiary crushing: After secondary crushing, the materials are further crushed by the tertiary crusher to the desired size.

Screening: The crushed materials are then screened to separate the required sizes and send them to the finished product pile.

The equipment required for a 500-600 TPH crushing production line includes a vibrating feeder, a jaw crusher, an impact crusher, a cone crusher, a vibrating screen, and a conveyor belt. The specific configuration of the production line depends on the material properties, production requirements, and other factors. Additionally, it’s important to note that the installation and maintenance of the equipment must be done properly to ensure the production line operates efficiently and safely.