Hard rock mining is a challenging and demanding industry that requires robust and efficient crushing systems to extract valuable minerals from the earth. In this article, we will explore the importance of crusher systems in hard rock mining operations and discuss their key features and benefits.

Hard rock mining involves the extraction of minerals, such as gold, silver, iron, copper, and zinc, from deep underground deposits. These deposits are typically found in solid rock formations that require extensive drilling, blasting, and excavation to access. Once the ore is brought to the surface, it needs to be processed to separate the valuable minerals from the surrounding rock.

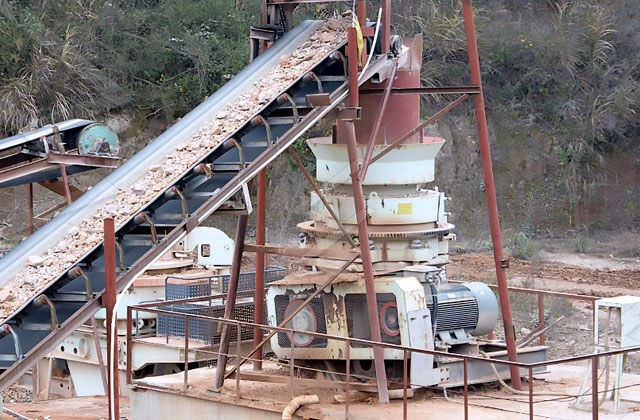

Crushing is a critical step in this processing chain, as it reduces the size of the ore particles, making it easier to extract and recover the valuable minerals. A crusher system refers to the machinery and equipment used to perform this crushing process. It typically consists of several components, including a primary crusher, secondary crushers, and screening equipment.

The primary crusher is usually the first step in the crushing process. It receives the raw ore directly from the mine and reduces its size to a manageable level. Jaw crushers or gyratory crushers are commonly used as primary crushers in hard rock mining operations. They are designed to handle large rocks and can process a wide range of materials.

Secondary crushers come into play after the primary crusher and further reduce the size of the ore. Common types of secondary crushers include cone crushers and impact crushers. These crushers are capable of producing smaller-sized materials and are essential for achieving the desired particle size for downstream processing.

Screening equipment is often used in conjunction with crushers to separate the crushed material into different sizes. This is important because it allows for better control over the final product and ensures that only the desired particle sizes are sent for further processing.

Efficiency and reliability are crucial aspects of crusher systems in hard rock mining. The crushers need to be able to handle large volumes of ore while operating continuously and reliably. Downtime can be extremely costly in mining operations, so crusher systems must be designed with robustness and durability in mind.

In recent years, technological advancements have improved the efficiency and performance of crusher systems in hard rock mining. For example, automation and remote monitoring technologies enable real-time monitoring of crusher performance, allowing for predictive maintenance and optimizing crusher settings for maximum throughput and product quality.

In conclusion, crusher systems play a vital role in hard rock mining operations. They are essential for reducing the size of ore particles, facilitating the extraction of valuable minerals. Efficient and reliable crusher systems are critical for maximizing productivity, minimizing downtime, and ensuring the safety of personnel and equipment. Continued advancements in technology will further enhance the performance and environmental sustainability of crusher systems in the future.