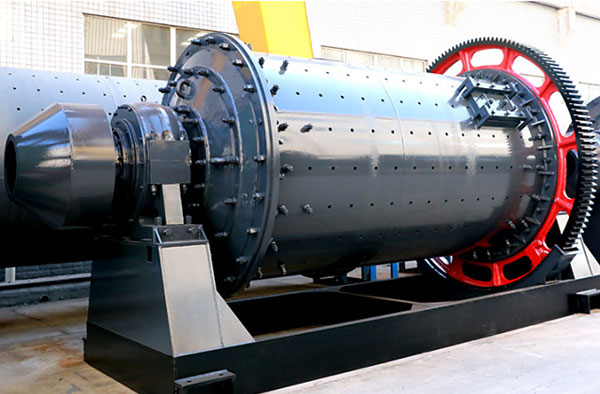

A horizontal wet ball mill is a type of grinding equipment used to finely grind materials into a slurry or suspension in water. It is widely used in including mineral processing, paint manufacturing, and chemical engineering. The design of a horizontal wet ball mill is critical to its efficient operation and performance. In this response, we will discuss the key design aspects of a horizontal wet ball mill.

Mill Structure:

The mill typically consists of a cylindrical shell that rotates on its axis. It is made of durable materials such as steel or rubber lined with wear-resistant liners to protect the shell from abrasion. The shell is closed at both ends and is equipped with inlet and outlet ports for the slurry and water.

Grinding Media:

The grinding media used in a wet ball mill are typically steel balls or ceramic beads. The size and type of media depend on the material being ground and the desired particle size. The media should be selected to provide efficient grinding and minimize wear on the mill components.

Milling Chamber:

The milling chamber is the space inside the mill where the grinding occurs. It is filled with the grinding media and the material to be ground. The chamber should be designed to optimize the grinding process, ensuring sufficient residence time for the material and promoting effective particle breakage.

Drive System:

The mill is driven by a motor and a gearbox, which provide the necessary power to rotate the mill shell. The drive system should be designed to handle the required load and provide smooth operation. It should also include safety features such as overload protection and emergency stops.

Water and Slurry Circulation:

A horizontal wet ball mill operates with water and slurry circulating through the mill. The water is used to control the mill temperature, lubricate the grinding media, and carry away the ground material. The slurry is a mixture of water and the ground material, which is discharged from the mill for further processing.

Control System:

An effective control system is essential for the efficient operation of a horizontal wet ball mill. It should include sensors to monitor key parameters such as mill speed, temperature, and pressure. The control system can adjust the mill parameters, such as the feed rate and water flow, to optimize the grinding process and ensure consistent product quality.

Safety Features:

Safety is of utmost importance in any industrial equipment, including a horizontal wet ball mill. The mill should be equipped with safety guards to prevent access to moving parts and potential hazards. Emergency stops and interlocks should be in place to shut down the mill in case of any abnormal conditions.

Maintenance and Accessibility:

The design should allow for easy maintenance and accessibility to critical components. This includes features such as removable liners, inspection ports, and access doors. Regular maintenance, including inspection, lubrication, and replacement of worn parts, is crucial to prolonging the mill’s lifespan and ensuring reliable operation.