In the world of mining and ore processing, the need for efficient and reliable equipment cannot be overstated. The cornerstone of any successful ore processing operation is the crusher, which plays a pivotal role in breaking down large rocks and ores into manageable sizes. When it comes to crushers, one name stands out for both quality and durability: the ore cone crusher. This article will delve into the key aspects that make a high-quality and durable ore cone crusher essential for any mining or ore processing operation.

Precision Engineering

High-quality ore cone crushers are the result of precision engineering. These machines are designed with a focus on achieving optimal crushing performance. Precision in design ensures that the crusher can handle a wide range of ores, from soft to extremely hard, without compromising efficiency or durability. Precision-engineered crushers are also more energy-efficient, reducing operating costs and environmental impact.

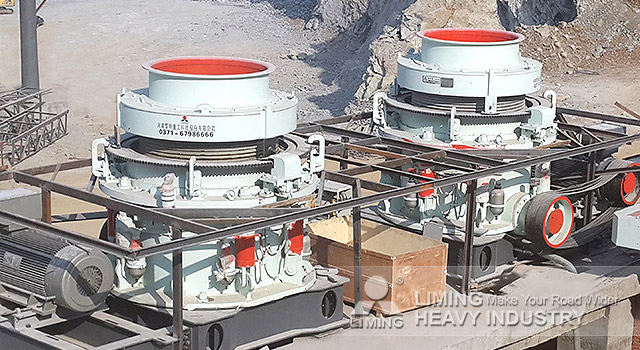

Robust Construction

Durability is a paramount concern in the mining industry, where heavy-duty equipment faces punishing conditions daily. A high-quality ore cone crusher is built with robust materials and construction techniques to withstand the rigors of continuous operation. High-strength steel frames, thick crusher walls, and reinforced components all contribute to the crusher’s longevity.

Wear-Resistant Components

The ore cone crusher’s internal components, such as the crushing chamber, mantle, and concave, are engineered with wear resistance in mind. These components are often made from high-quality materials, such as manganese steel, which can endure the abrasive nature of ore processing. Wear-resistant components ensure a longer lifespan for the crusher, reducing downtime and maintenance costs.

Advanced Crushing Technology

Modern ore cone crushers incorporate advanced crushing technologies that enhance their performance. These include innovations like hydraulic adjustment systems, which allow for precise control of the crusher’s settings, and automation features that optimize the crushing process. Such advancements improve productivity and reduce the risk of human error.

Versatility

A high-quality ore cone crusher is a versatile tool capable of crushing various types of ores, including copper, gold, iron, and more. Its versatility makes it suitable for different mining applications, from primary crushing in large mining operations to secondary and tertiary crushing in processing plants.

Efficient Energy Consumption

Efficiency is crucial in the mining industry to reduce operational costs and environmental impact. High-quality ore cone crushers are designed to maximize energy efficiency. Features such as a well-designed crushing chamber, adjustable eccentric throw, and optimized speed contribute to reduced energy consumption per ton of crushed ore.

Maintenance-Friendly Design

Downtime is costly in the mining industry, making maintenance a critical consideration. A durable ore cone crusher is designed with ease of maintenance in mind. Accessible service points, durable components, and clear maintenance instructions contribute to quicker and more cost-effective maintenance procedures.

Safety Features

Safety is paramount in any mining operation. High-quality ore cone crushers come equipped with safety features, including emergency stop buttons, protective guards, and safety interlocks. These features help protect operators and maintenance personnel from accidents.

A high-quality and durable ore cone crusher is an indispensable tool in the world of mining and ore processing. Precision engineering, robust construction, wear-resistant components, advanced technology, versatility, energy efficiency, maintenance-friendliness, and safety features all combine to make these crushers a reliable choice for efficient ore crushing operations.

Investing in a high-quality ore cone crusher is not just a matter of equipment procurement but a strategic decision that can significantly impact the efficiency and profitability of a mining or ore processing operation. With the right crusher, you can ensure consistent production, reduce downtime, and minimize maintenance costs, all while maximizing safety and environmental responsibility.