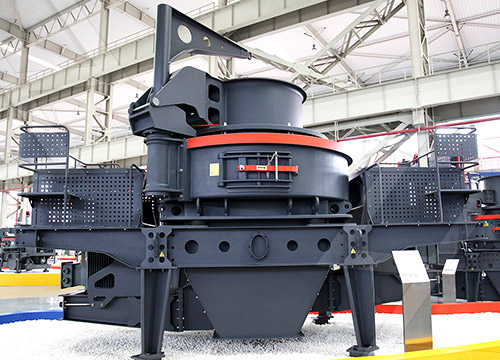

A vertical shaft crusher for zircon sand and gravel is a specialized piece of equipment used in the mining and construction industry to crush and shape hard and abrasive materials such as zircon sand and gravel. In this article, we will explore the key features, benefits, and applications of vertical shaft crushers for zircon sand and gravel.

Understanding Vertical Shaft Crushers

Vertical shaft crushers, also known as vertical shaft impactors (VSI), are machines designed to crush materials by utilizing the principle of high-speed impact and attrition. These crushers consist of a vertical shaft with a rotor at its center and anvils or impellers that throw the material against a stationary surface. This action generates high-speed collisions, effectively breaking down the material into smaller particles.

Features of Vertical Shaft Crusher:

Vertical Shaft Impactor (VSI): The core component of a vertical shaft crusher is the VSI, which consists of a vertical rotor that spins at high speeds. This rotor throws the material against a hard surface (usually anvils or rock-lined crushing chambers), resulting in the creation of smaller particles through high-velocity impact.

Crushing Chamber Design: Vertical shaft crushers are designed with multiple crushing chambers to optimize the crushing process. These chambers can be easily adjusted to control the particle size and shape of the crushed material.

High Crushing Efficiency: Vertical shaft crushers are known for their high crushing efficiency. They can produce cubical-shaped end products with excellent particle size distribution, making them suitable for various applications.

Variable Speed Drive: Many modern vertical shaft crushers come equipped with variable speed drives, allowing operators to adjust the rotor speed to meet specific production requirements and optimize energy consumption.

Benefits of Using Vertical Shaft Crushers for Zircon Sand and Gravel:

Product Quality: Vertical shaft crushers produce high-quality end products with consistent particle size and shape. This is crucial for applications where precise material specifications are required.

Cost Efficiency: These crushers can significantly reduce operating and maintenance costs. Their efficient crushing process minimizes wear and tear on components, leading to longer equipment lifespan.

Versatility: Vertical shaft crushers are versatile and can handle a wide range of materials, including zircon sand and gravel, as well as harder rocks and minerals. This versatility makes them suitable for various industries, from mining to construction.

Environmental Friendliness: Some vertical shaft crushers are designed to be more environmentally friendly, with features like low dust emission and noise levels, reducing their impact on the surrounding environment.

Applications of Vertical Shaft Crushers for Zircon Sand and Gravel:

Mining Industry: Vertical shaft crushers are commonly used in the mining industry to crush hard and abrasive materials like zircon sand and gravel. They are used in the production of aggregates for concrete, asphalt, and road construction.

Construction Industry: These crushers are also used in the construction industry for producing high-quality construction materials. They can crush and shape gravel and sand for use in concrete production, ensuring the durability of structures.

Manufactured Sand Production: Vertical shaft crushers are employed in the production of manufactured sand, which is used as a substitute for natural sand in the construction industry. This helps conserve natural resources and reduce environmental impacts associated with sand extraction.

Vertical shaft crusher for zircon sand and gravel is a versatile and efficient piece of equipment that plays a crucial role in various industries. Its ability to produce high-quality end products, cost-efficiency, and versatility make it an essential tool for mining and construction operations. Additionally, its environmentally friendly features contribute to sustainable and responsible resource utilization.