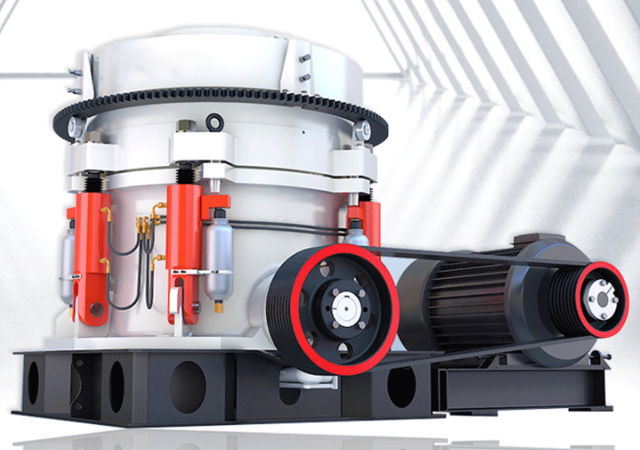

The concrete hydraulic cone crusher is a specialized machine developed for the production of high-quality aggregate materials in the construction industry. This type of cone crusher is designed to crush hard and abrasive materials, making it ideal for applications such as mining, quarrying, and recycling of concrete.

The dimensions of a concrete hydraulic cone crusher can vary depending on the specific model and manufacturer. However, a typical hydraulic cone crusher used in concrete crushing applications may have the following approximate dimensions:

- Height: The height of the crusher can range from several feet to over 10 feet, depending on the design and capacity of the machine. This height is determined by the vertical arrangement of the main components, including the frame, crusher chamber, and hydraulic system.

- Width: The width of the crusher is influenced by the size of the crushing chamber and the arrangement of the components. It typically ranges from several feet to more than 10 feet. The wider design allows for a larger feed opening, enabling the crusher to process larger pieces of concrete or other materials.

- Length: The length of the crusher depends on the design of the frame and the location of the drive system. It can vary from several feet to over 20 feet. A longer crusher allows for a more gradual and effective crushing process, especially when dealing with hard and abrasive materials.

- Weight: The weight of the concrete hydraulic cone crusher is a crucial factor in its transport, installation, and overall stability. The weight can vary significantly depending on the size and capacity of the machine. It may range from several tons to over 100 tons for larger models.

- Feed Opening Size: The feed opening size is a critical parameter that determines the maximum size of the material that the crusher can effectively process. For a concrete hydraulic cone crusher, the feed opening is designed to accommodate large pieces of concrete or other aggregates, typically ranging from several inches to a foot or more in diameter.

- Power and Capacity: The hydraulic cone crusher is powered by a combination of electric motors and hydraulic systems. The power and capacity of the crusher depend on the specific model and are designed to handle a certain throughput of material per hour.

- Operating Pressure: Hydraulic cone crushers operate under high hydraulic pressure, which is crucial for the efficient crushing of hard materials. The operating pressure can vary depending on the design and specifications of the hydraulic system.

The concrete hydraulic cone crusher is a powerful and efficient machine designed for the demanding requirements of the construction industry. Its dimensions, including height, width, length, weight, feed opening size, power, capacity, and operating pressure, are carefully engineered to ensure optimal performance in crushing hard and abrasive materials, particularly in concrete recycling and aggregate production applications.