Gyratory and cone crushers are two types of rock crushing equipment commonly used in the mining and aggregate industries. Both types of crushers have unique features and are designed to handle different types of materials, but they share some similarities in their operation and application. In this discussion, we will explore the features of gyratory and cone crushers in detail.

Gyratory Crushers:

Gyratory crushers are characterized by a conical-shaped crushing head mounted within a vertical, conical bowl. The crushing head is supported by a spider assembly, which is typically mounted on a central vertical shaft. Here are some key features of gyratory crushers:

- Large Crushing Capacity: Gyratory crushers are known for their ability to handle large capacities of material. This is due to the large diameter of the crushing head and the eccentric motion of the main shaft, which allows for a high throughput of material.

- Continuous Operation: Gyratory crushers are designed for continuous operation, making them suitable for high-volume crushing applications. The crushing action is continuous as the crushing head gyrates within the bowl, crushing the material against the concave liners.

- Adjustable Discharge Setting: Gyratory crushers typically have a hydraulic mechanism for adjusting the discharge setting. This allows operators to control the product size output and optimize the crusher’s performance for different applications.

- Safety Features: Gyratory crushers are equipped with safety features such as hydraulic overload protection and a self-tightening concave liner. These features help prevent damage to the crusher and ensure safe operation, particularly in the event of an overload or tramp metal entering the crushing chamber.

- Primary Crushing Application: Gyratory crushers are often used as primary crushers in large mining operations. They are capable of handling large feed sizes and are ideal for primary crushing of hard and abrasive materials.

Cone Crushers:

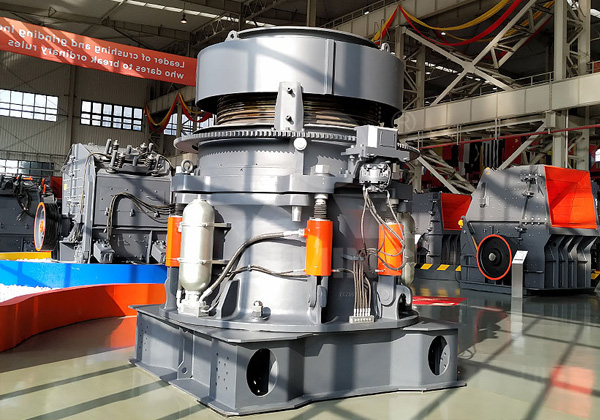

Cone crushers, also known as conical crushers, operate similarly to gyratory crushers but feature a different crushing chamber design. Here are some key features of cone crushers:

- Conical Crushing Chamber: Cone crushers have a conical-shaped crushing chamber that tapers from a larger inlet opening to a narrower outlet opening. This design allows for a more efficient compression crushing action compared to gyratory crushers.

- Versatility in Crushing: Cone crushers are versatile machines suitable for secondary, tertiary, and even quaternary crushing stages. They are often used in aggregate production, mining operations, and recycling applications.

- Eccentric Motion: Cone crushers utilize an eccentric motion to squeeze the material between the mantle and concave liner. This action produces a finer product size compared to gyratory crushers, making cone crushers suitable for producing cubical-shaped aggregates.

- Adjustable CSS (Closed Side Setting): Cone crushers typically feature a hydraulic or mechanical mechanism for adjusting the CSS, which controls the product size output. Operators can optimize the CSS to achieve the desired product gradation and particle shape.

- Portability and Mobility: Cone crushers are available in stationary, portable, and mobile configurations, making them suitable for various crushing applications. Portable cone crushers are particularly popular for on-site crushing in construction and demolition projects.

In summary, gyratory and cone crushers are both essential pieces of equipment in the mining and aggregate industries, each with its own unique features and advantages. Gyratory crushers excel in high-capacity primary crushing applications, while cone crushers offer versatility and efficiency in secondary and tertiary crushing stages. Both types of crushers play a crucial role in modern crushing operations, contributing to the production of high-quality aggregates for construction and other industries.