Due to the continuous demand for lithium in new energy technologies, lithium production is expected to continue to increase. Global lithium production is growing rapidly, with an estimated 70% increase in production over the past five years. Although hard-rock pegmatite ores have been the main source of lithium, in recent years the development of onshore salt lakes in Argentina, Bolivia, Chile, and China has accounted for a major share of lithium production. In addition, Australia, Canada, China, Finland, Serbia and Mexico have also developed or are conducting some pegmatite-type lithium ore mining projects.

Various beneficiation methods for separating lithium minerals from hard rock pegmatite ores (spodumene, lithium feldspar, lepidolite and lithium phosphate aluminum, etc.). Dense media beneficiation and flotation are the main beneficiation methods used in many beneficiation plants around the world. The success of these methods in isolating lithium minerals from ores depends largely on the specific gravity and differences in chemical and physical properties between lithium minerals and associated gangue minerals.

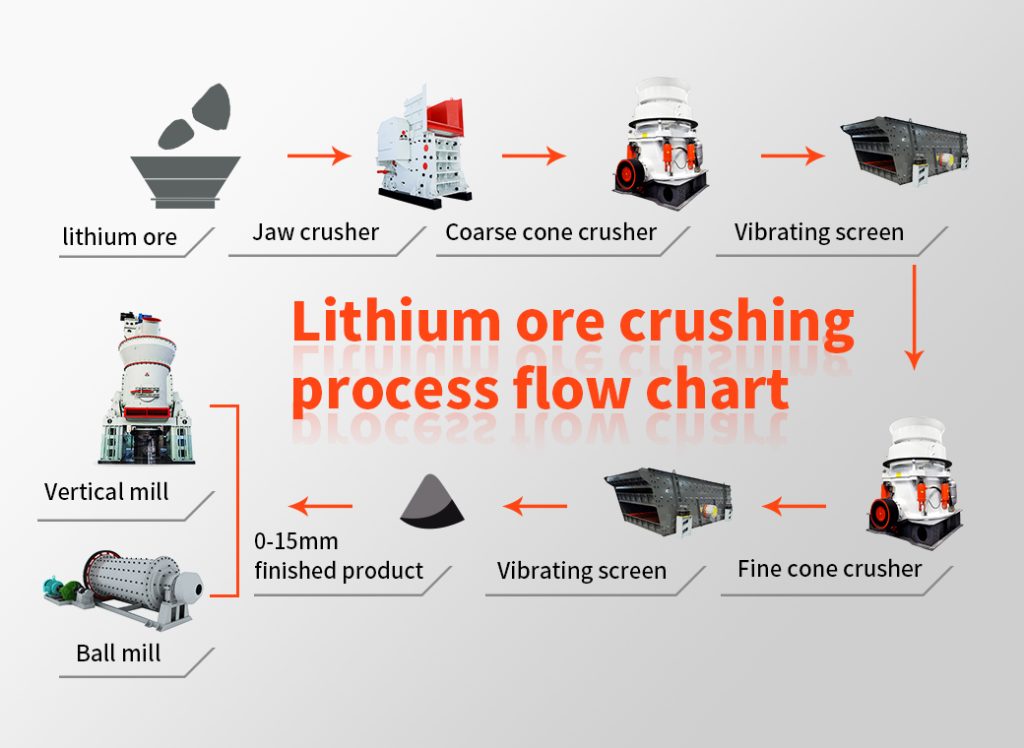

The beneficiation process of lithium ore includes crushing, grinding, and sorting. Crushing is to turn large pieces of lithium ore or materials into small pieces to meet the particle size requirements of the user department or the next process for lithium ore products. According to the crushing particle size, it can be divided into coarse crushing, medium crushing and fine crushing. Sorting is also called lithium ore separation or sorting. It uses a certain beneficiation method to separate the useful minerals in lithium ore from gangue minerals and different useful minerals, and enrich them separately. The sorted products include lithium ore concentrate and lithium ore tailings.