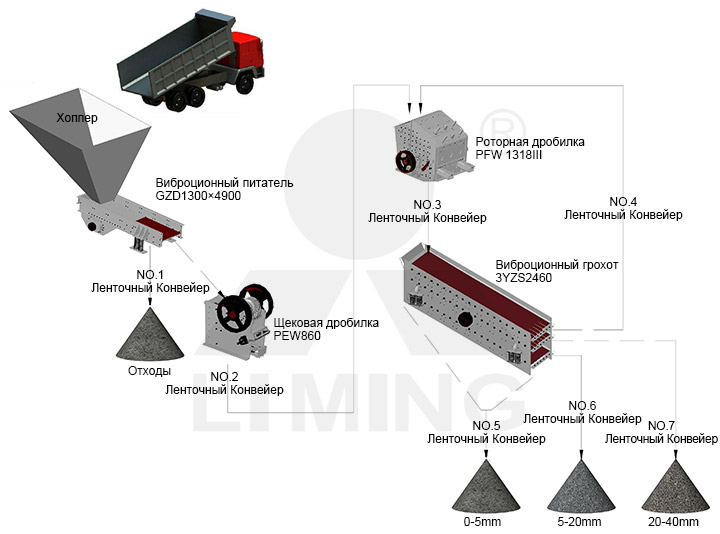

A 300-400TPH crushing production line typically refers to a whole set of stone crushing and screening equipment with a capacity of 300-400 tons per hour. The primary crushing stage includes a jaw crusher or a gyratory crusher, while the secondary crushing stage involves a cone crusher or an impact crusher. The crushed stones are then screened by a vibrating screen to obtain different sizes of stones that meet the required specifications.

The production line may also include other equipment, such as a feeder, a conveyor belt, and a dust removal system to ensure a smooth and efficient production process. The specific configuration of the production line may vary depending on the type of stones to be crushed and the customer’s requirements.

The 300-400 TPH crushing production line is suitable for a wide range of materials, including limestone, granite, basalt, river pebble, and other hard and abrasive materials. With its high capacity, it can easily handle even the toughest of materials and ensure consistent and reliable performance.

The main components of the 300-400 TPH crushing production line include:

Jaw crusher: The jaw crusher is the primary crusher in the crushing production line. It has a large feed opening and a high crushing ratio, making it ideal for large-scale crushing operations.

Cone crusher: The cone crusher is used for secondary crushing. It has a high crushing efficiency and can produce a wide range of particle sizes.

Vibrating screen: The vibrating screen is used to screen the crushed materials and separate them into different sizes. It can effectively improve the efficiency of the production line and reduce the number of secondary crushing operations.

Feeder: The feeder is used to transport the raw materials to the jaw crusher or cone crusher. It can ensure a continuous and stable supply of materials to the crushing production line.

Conveyor: The conveyor is used to transport the crushed materials to the vibrating screen or storage bin. It is an important component of the crushing production line and can effectively improve the efficiency of material handling.

The 300-400 TPH crushing production line has several advantages:

High capacity: The production line has a high capacity and can handle large volumes of raw materials.

High efficiency: The production line is designed to be highly efficient, with low energy consumption and high crushing efficiency.

Good product shape: The production line can produce a variety of particle sizes, with good product shape and high quality.

Easy maintenance: The production line is easy to maintain and requires minimal downtime, ensuring that the production process is continuous and stable.

Cost-effective: The production line is cost-effective, with a low cost per ton of production.

The 300-400TPH crushing production line is suitable for large-scale stone crushing projects, such as construction sites, highway construction, and mining sites. It requires a significant investment and careful planning to ensure the smooth operation of the equipment and the achievement of the desired output.