Cone crushers are essential equipment in the mining and aggregate industries, used for crushing hard and abrasive materials. Innovations in this field can significantly improve efficiency, reduce maintenance costs, and enhance overall productivity. Several innovative products have emerged to address challenges and optimize cone crusher performance.

Lubrication Systems:

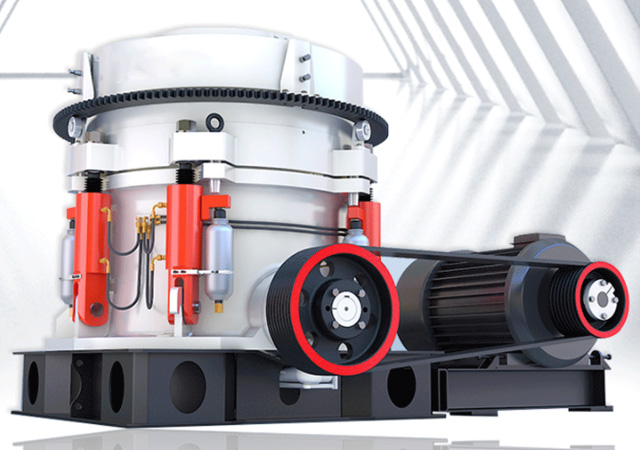

One critical aspect of cone crusher maintenance is proper lubrication. Traditional lubrication systems may face challenges in ensuring consistent and adequate lubrication. Innovative solutions, such as automated lubrication systems, have emerged to address this. These systems can precisely deliver the right amount of lubrication at the right intervals, reducing wear and tear on components and extending the lifespan of the crusher.

Cone Crusher Liner Solutions:

Wear and tear on cone crusher liners are inevitable, impacting the crusher’s overall efficiency. Innovations in liner technology aim to extend the lifespan of liners and improve their wear resistance. High-quality materials, such as advanced alloys and composite materials, are being used to manufacture durable liners that withstand the harsh conditions of crushing operations.

Remote Monitoring and Control:

The integration of IoT (Internet of Things) technology allows for remote monitoring and control of cone crushers. This innovation enables operators to track the machine’s performance, receive real-time data on operating conditions, and make informed decisions to optimize efficiency and prevent unexpected downtime. Remote diagnostics also facilitate predictive maintenance, reducing the likelihood of costly equipment failures.

Adjustable Eccentric Throw:

The eccentric throw of a cone crusher plays a crucial role in determining the crusher’s performance and product quality. Some innovative cone crushers now feature adjustable eccentric throws, allowing operators to optimize the crusher’s throughput and product size distribution based on the specific needs of the application. This adaptability enhances the crusher’s versatility in different operating conditions.

Energy-Efficient Cone Crushers:

Energy consumption is a significant concern in the mining industry. Innovations in cone crusher design and technology have led to the development of more energy-efficient crushers. This includes the use of advanced drive systems and hybrid power options, reducing the overall environmental impact and operational costs.

Automated Control Systems:

Advanced control systems have been introduced to automate cone crusher operations, ensuring optimal performance and minimizing the risk of human error. These systems can adjust settings in real-time based on the feed material, load conditions, and other variables, maximizing efficiency and throughput while minimizing the risk of overloading or damaging the crusher.

Modular Cone Crushers:

Modular cone crushers are designed with easy assembly and disassembly in mind. This innovation allows for quicker maintenance and component replacement, reducing downtime and increasing overall operational efficiency. Modular designs also provide flexibility for future upgrades or modifications to meet changing production requirements.

Innovative products for cone crushers continue to evolve, addressing various challenges in the mining and aggregate industries. These advancements aim to enhance reliability, increase efficiency, and reduce overall operational costs, ultimately contributing to a more sustainable and productive crushing process. As technology continues to progress, it is likely that further innovations will emerge, further optimizing cone crusher performance.