Hammer crusher is a kind of mechanical equipment that mainly relies on impact energy to complete material crushing. The equipment not only has high crushing rate and high efficiency, but also has uniform crushing particle size and adjustable size. Therefore, it is more suitable to use soft limestone for crushing. The advantages of hammer crusher used in limestone production are high production efficiency, low power … Read More →

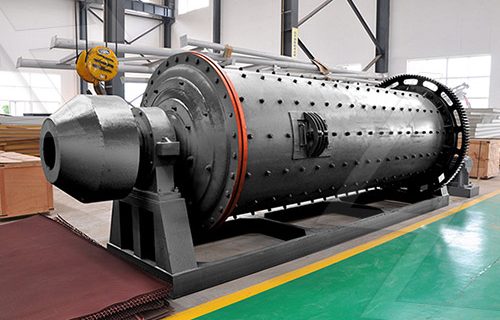

Choose Ball Mill For Cement Plant

How to choose the model of the ball mill in the cement plant is mainly based on the grinding needs of the user. The fineness required by the user is different, the production capacity is different, and the model of the ball mill selected is also different, but at the same time, the maximum feed size and particle size of the cement ball mill must … Read More →

Types of Mineral Grinding Mills

Mineral grinding equipment is what we often call mineral grinding mills, which are often used in the mineral processing industry and some industrial pulverizing industries. There are many types of mineral grinding equipment, and each type has different performances. So, what are the mineral grinding equipment? Which type is better to use? This article gives a detailed introduction to the types of mineral grinding mills. … Read More →

Granite Crusher, Granite Sand Making plant

The granite is sent to the jaw crusher by the feeder for coarse crushing, and then sent to the cone crusher of the secondary crushing equipment by the conveyor belt for medium and fine crushing. The crushed stone is screened by the vibrating screen, and those that meet the discharge requirements are sent to the finished product pile by the belt conveyor, and those that … Read More →

Sand making production line

Finished particle size: 0-5mmProcessing capacity: 50-500T/H.Composition equipment: vibrating feeder, jaw crusher, sand making machine, vibrating screen, sand washing machine, belt conveyor and other equipment; Process flow of sand making production lineThe stone is evenly sent to the jaw crusher by the vibrating feeder for coarse crushing, the coarsely crushed material is sent to the fine jaw crusher or the impact crusher for re-crushing, and the … Read More →