Lithium is found all around the world in different concentrations, and there are different ways to extract it from the Earth. A new extraction technology offers a superior method to production so the demand for lithium can be filled. Lithium carbonate, as the main raw material for new energy batteries, cannot be obtained directly in nature. Lithium carbonate that can be used is obtained after … Read More →

Classification of gravel aggregate crushing equipment

Gravel aggregate crusher can be divided according to its crushing principle: laminated type, roller type, impact type, hammer type. The impact crusher is the crusher with the best discharge particle shape. The so-called best discharge particle shape means that the crushed materials all present a polygonal diamond shape with regular particle shape, which is more suitable for commercial concrete mixing plants. The impact crusher mainly … Read More →

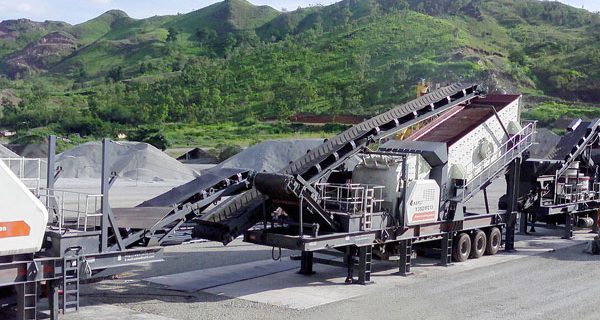

Sand and gravel processing mobile crusher

Sand and gravel are commonly used materials in road and bridge construction. Whether it is cement or concrete, sand and gravel materials are inseparable. The sand and gravel materials required in road and bridge construction need to be processed and crushed by crushing machinery to produce crushed stone particles that meet the needs of construction. The mobile crusher is the product of the needs of … Read More →

Lithium ore beneficiation market prospect

Due to the continuous demand for lithium in new energy technologies, lithium production is expected to continue to increase. Global lithium production is growing rapidly, with an estimated 70% increase in production over the past five years. Although hard-rock pegmatite ores have been the main source of lithium, in recent years the development of onshore salt lakes in Argentina, Bolivia, Chile, and China has accounted … Read More →

Spodumene beneficiation and crushing process

The main equipment of the spodumene beneficiation and crushing process includes the jaw crusher for coarse crushing of spodumene, the cone crusher for fine crushing of spodumene, and the storage of crushed spodumene. Silo, vertical mills for grinding spodumene, cyclones for classifying spodumene, flotation machines for flotation of spodumene; cyclones and vertical mills It forms a closed-circuit grinding and grading cycle, which improves the efficiency … Read More →

Lithium ore beneficiation process flow

The lithium ore beneficiation process flow is a combination of lithium ore through a series of processes such as crushing, screening, grinding, grading, stirring, flotation, thickening, and filtration. It is the main step in the production of lithium carbonate and lithium hydroxide. The most reasonable scheme of lithium ore beneficiation principle: crusher, ball mill, jig, flotation machine. The lithium ore beneficiation process flow is as … Read More →

Cone crusher discharge efficiency

Cone crushers are divided into single-cylinder cone crushers and multi-cylinder cone crushers. The cone crusher adopts the lamination crushing method, and it is the key to improve the efficiency of the cone crusher, reduce the energy consumption, and increase the market competitiveness. Feed particle size of cone crusherFor cone crushers, different types or models can process different feed sizes. If the feed size is not … Read More →

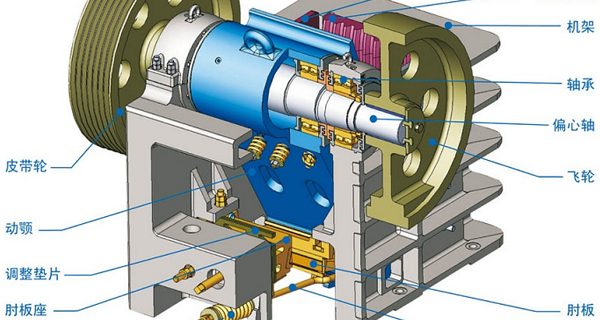

Jaw Crusher Parts Maintenance

Because the thrust plate of the jaw crusher is made of cast iron, and the thrust plate seat is mostly steel casting or variant cast iron, the thrust plate plays the role of transmitting motion and force, and also plays a role in safety protection and adjustment of the size of the ore discharge. . Because the thrust plate is installed at the lower part … Read More →

Quartz sand crushing production line

The quartz sand crushing production line adopts the crushing and grading operation process to crush the natural quartz sandstone ore and make the impurities and minerals reach the monomer dissociation state, and then obtain the raw quartz sand that meets the particle size requirements through the grading operation, which is used for subsequent quartz sand removal. Preparing for homework. Quartz sand crushing production line equipmentThe … Read More →

Best Granite Crushing Plant

The best granite crushing plant is a new type of crushing equipment specially designed and developed for the characteristics of granite, integrating similar crusher technologies at home and abroad, and optimizing the main technical parameters. It has a high degree of automation, low operating costs, high crushing rate, energy saving, With the advantages of large output, less pollution and easy maintenance, it is the equipment … Read More →