Non-metallic ore extraction involves the process of obtaining valuable minerals or rocks from deposits that do not contain metallic elements. The primary crusher plays a crucial role in this extraction process by reducing the size of the ore into smaller, more manageable pieces. In this article, we will explore the significance of the primary crusher in non-metallic ore extraction and discuss its key functions and … Read More →

Investment cost of river pebble crushing plant

The investment cost of a river pebble crushing plant can vary depending on various factors such as the scale of the plant, the equipment and machinery required, the location of the plant, and the market conditions. However, I can provide you with a general overview of the investment cost, considering the typical requirements of such a plant. A river pebble crushing plant is designed to … Read More →

300-400TPH stone crushing production line

A 300-400TPH stone crushing production line is a large-scale production line that is designed to crush and process various types of rocks, such as limestone, granite, basalt, and other types of stones. This production line is typically used for the production of construction materials, such as concrete, asphalt, and other types of aggregates. The stone crushing production line consists of several processes, including crushing, screening, … Read More →

Cement industry vertical roller mill

The cement industry is one of the largest and most important industrial sectors in the world. The production of cement involves a complex process that requires a range of specialized equipment, including crushers, mills, and kilns. One key piece of equipment used in the cement production process is the vertical roller mill. A vertical roller mill is a type of industrial equipment used to crush … Read More →

Gyratory crusher details introduce

A gyratory crusher is a type of primary crusher that is used in mines and ore processing plants to crush rocks and ores into smaller sizes. It consists of a concave surface and a conical head, with the head being inclined at an angle to the concave surface. The crushing action is caused by the closing of the gap between the concave surface and the … Read More →

Ore Processing Gyratory Crusher Details

Ore processing is a critical step in the mining industry, as it involves crushing and grinding rocks to extract valuable minerals. One of the key pieces of equipment used in this process is the gyratory crusher, which is designed to crush large rocks into smaller pieces. In this article, we will provide a detailed overview of gyratory crushers and their role in ore processing. What … Read More →

High-quality energy-saving ball mill

Ball mills are widely used in the mining industry, cement industry, and various other industrial sectors for grinding and processing raw materials. However, traditional ball mills are not energy-efficient, and they consume a lot of electricity. This not only increases production costs but also has a negative impact on the environment. Therefore, high-quality energy-saving ball mills have been developed to address these issues. A high-quality … Read More →

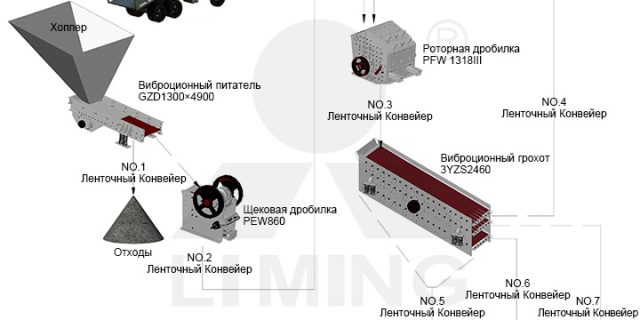

500-600TPH crushing production line

A 500-600 TPH crushing production line is a large-scale production line used for the crushing of limestone, granite, basalt, river stone, and other materials. The production line is designed with several stages of crushing, including primary crushing, secondary crushing, and tertiary crushing. The final product size is usually between 0-5mm, 5-10mm, 10-20mm, 20-30mm, and other specifications. Components of a 500-600TPH Crushing Production LineA crushing production … Read More →

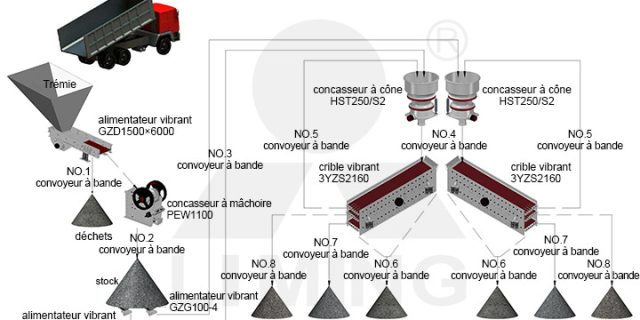

300-400TPH crushing production line

A 300-400TPH crushing production line typically refers to a whole set of stone crushing and screening equipment with a capacity of 300-400 tons per hour. The primary crushing stage includes a jaw crusher or a gyratory crusher, while the secondary crushing stage involves a cone crusher or an impact crusher. The crushed stones are then screened by a vibrating screen to obtain different sizes of … Read More →

Grinding Mill Global Market Report

The global grinding mill market can be segmented based on product type, application, and region. Based on product type, the market can be segmented into vertical roller mills, ball mills, and others. The ball mills segment is expected to hold the largest share of the market, owing to its widespread use in various industries. Based on application, the market can be segmented into mining, construction, … Read More →