The cement industry is one of the largest and most important industrial sectors in the world. The production of cement involves a complex process that requires a range of specialized equipment, including crushers, mills, and kilns. One key piece of equipment used in the cement production process is the vertical roller mill. A vertical roller mill is a type of industrial equipment used to crush … Read More →

Gyratory crusher details introduce

A gyratory crusher is a type of primary crusher that is used in mines and ore processing plants to crush rocks and ores into smaller sizes. It consists of a concave surface and a conical head, with the head being inclined at an angle to the concave surface. The crushing action is caused by the closing of the gap between the concave surface and the … Read More →

Ore Processing Gyratory Crusher Details

Ore processing is a critical step in the mining industry, as it involves crushing and grinding rocks to extract valuable minerals. One of the key pieces of equipment used in this process is the gyratory crusher, which is designed to crush large rocks into smaller pieces. In this article, we will provide a detailed overview of gyratory crushers and their role in ore processing. What … Read More →

High-quality energy-saving ball mill

Ball mills are widely used in the mining industry, cement industry, and various other industrial sectors for grinding and processing raw materials. However, traditional ball mills are not energy-efficient, and they consume a lot of electricity. This not only increases production costs but also has a negative impact on the environment. Therefore, high-quality energy-saving ball mills have been developed to address these issues. A high-quality … Read More →

Limestone Mobile Crusher Suppliers

Limestone is a sedimentary rock composed mostly of calcium carbonate (CaCO3) that has many industrial applications. It is commonly used as a building material, as a raw material in the production of cement and lime, and as a filler in various products such as paints, rubber, and plastics. Limestone is also widely used in the construction of roads and as an aggregate in concrete. With … Read More →

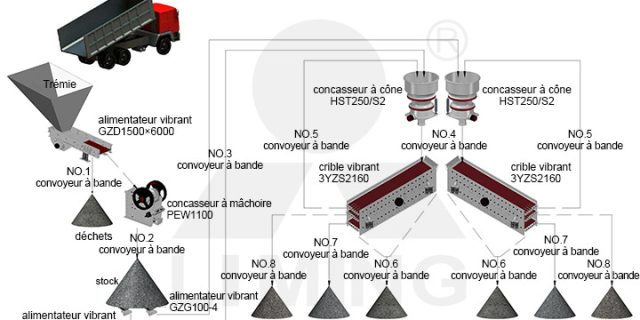

500-600TPH crushing production line

A 500-600 TPH crushing production line is a large-scale production line used for the crushing of limestone, granite, basalt, river stone, and other materials. The production line is designed with several stages of crushing, including primary crushing, secondary crushing, and tertiary crushing. The final product size is usually between 0-5mm, 5-10mm, 10-20mm, 20-30mm, and other specifications. Components of a 500-600TPH Crushing Production LineA crushing production … Read More →

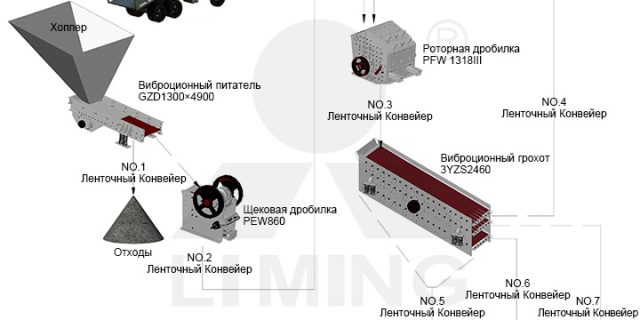

300-400TPH crushing production line

A 300-400TPH crushing production line typically refers to a whole set of stone crushing and screening equipment with a capacity of 300-400 tons per hour. The primary crushing stage includes a jaw crusher or a gyratory crusher, while the secondary crushing stage involves a cone crusher or an impact crusher. The crushed stones are then screened by a vibrating screen to obtain different sizes of … Read More →

Grinding Mill Global Market Report

The global grinding mill market can be segmented based on product type, application, and region. Based on product type, the market can be segmented into vertical roller mills, ball mills, and others. The ball mills segment is expected to hold the largest share of the market, owing to its widespread use in various industries. Based on application, the market can be segmented into mining, construction, … Read More →

ultrafine mill for mineral grinding

Ultrafine mill is a type of grinding machine that is commonly used to grind mineral materials into very fine powders. It is widely used in industries such as metallurgy, building materials, chemical engineering, mining, and more. The ultrafine mill is designed to produce ultra-fine powders, typically less than 10 microns in size. This article will discuss the features, benefits, and applications of ultrafine mill for … Read More →

Cement powder production grinding mill

Cement powder production is a critical process in the construction industry, where it serves as the main ingredient for producing concrete. The production process involves grinding raw materials such as limestone, clay, and shale, to a fine powder using a cement grinding mill. This process is necessary to create a homogenous mixture that can be used in the production of high-quality cement. Cement powder grinding … Read More →