In the heart of Africa lies Rwanda, a country known for its stunning landscapes, vibrant culture, and emerging economy. As Rwanda continues to develop and expand its industrial sector, the demand for efficient and reliable machinery has become paramount. Among the critical pieces of equipment in the mining and construction industries is the cone crusher, which plays a pivotal role in crushing and processing various materials. However, to meet the growing needs of Rwanda’s burgeoning industries, it is imperative to enhance the production capacity of cone crushers in the region.

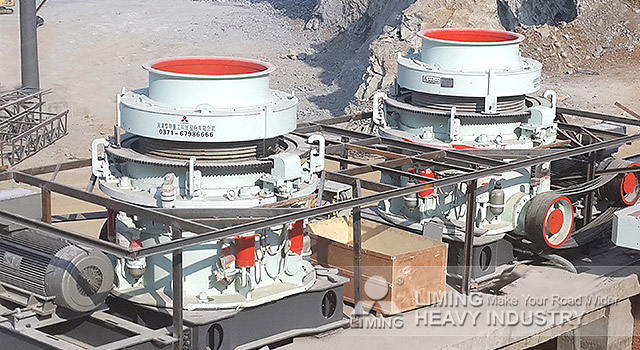

Cone crushers are widely used in Rwanda’s mining and construction sectors for crushing a variety of materials, ranging from limestone to granite and from gravel to ore. These versatile machines are instrumental in reducing the size of raw materials into finer particles, making them suitable for further processing or use in construction projects. However, despite their importance, cone crushers often face challenges related to production capacity, efficiency, and reliability.

One of the primary factors influencing cone crusher production capacity is the design and configuration of the machine itself. Modern cone crushers are engineered to deliver high performance and efficiency, but their capacity can still be optimized through various means. For instance, optimizing the crusher’s chamber geometry, mantle, and concave profiles can improve crushing efficiency and throughput. Additionally, advancements in hydraulic systems and automation technologies enable better control over the crusher’s operation, leading to increased productivity.

Furthermore, proper maintenance and regular servicing are essential for maximizing the production capacity of cone crushers. Routine inspections, lubrication, and timely replacement of wear parts such as liners and bearings can prevent unexpected downtime and ensure consistent performance. In Rwanda, investing in comprehensive maintenance programs and training for operators can significantly enhance the reliability and longevity of cone crushers, thereby increasing their production capacity.

Moreover, the availability of skilled workforce and technical expertise is crucial for optimizing cone crusher production capacity in Rwanda. By providing training and educational opportunities for engineers, technicians, and operators, the country can develop a proficient workforce capable of operating and maintaining cone crushers at peak efficiency. Collaborating with international partners and industry experts can also facilitate knowledge transfer and skill development, further bolstering Rwanda’s capacity in crusher technology.

In addition to technical enhancements, improving infrastructure and logistical support can contribute to boosting cone crusher production capacity in Rwanda. Efficient transportation networks, access to quality spare parts, and reliable power supply are essential for the seamless operation of crushing plants. Therefore, investing in infrastructure development projects and strengthening supply chains will create a conducive environment for the mining and construction sectors to thrive.