A high-quality silica sand ball mill is an essential piece of equipment in the production of ceramics, paints, minerals, and many other industries. It operates by grinding and blending raw materials into a fine powder, which is further used for various purposes such as forming ceramic bodies, glazes, and more. In this essay, we will delve into the importance of a high-quality silica sand ball mill, its components, working principle, and its significance in various industries.

Components of a Silica Sand Ball Mill:

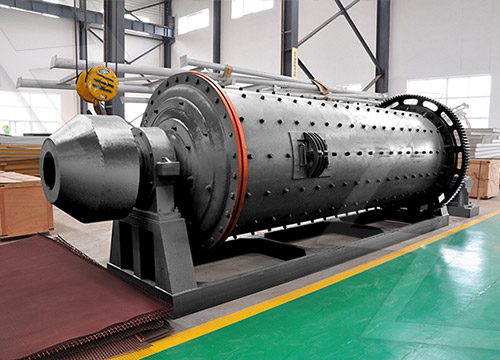

A silica sand ball mill consists of various components that work together to achieve efficient grinding and blending of materials. Some key components include:

Cylinder: The mill’s cylindrical shell houses the grinding medium and the material to be processed.

Grinding Medium: These are usually spherical balls or cylindrical rods made of various materials, including steel, ceramic, or other specialized alloys, designed to efficiently grind the material.

Motor: The motor provides the necessary power to rotate the mill’s cylinder and the grinding medium inside it.

Liners: The inner surface of the mill cylinder is often lined with protective materials, such as rubber or metal, to prevent wear and tear.

Inlet and Outlet: The mill has openings for material and grinding medium to be fed in and discharged out after processing.

Working Principle:

The working principle of a silica sand ball mill revolves around the rotation of the mill cylinder. As the mill rotates, the grinding medium (balls or rods) cascade and tumble over the material, causing it to break down into finer particles. The rotation of the cylinder ensures that the grinding medium impacts the material continuously, leading to the desired particle size reduction. The speed and direction of rotation, as well as the size and composition of the grinding medium, play a crucial role in achieving the desired grind.

Importance of High Quality:

The quality of a silica sand ball mill directly impacts the quality of the final product. High-quality ball mills ensure uniform and efficient grinding, leading to consistent particle size distribution. This is vital for achieving desired product properties, whether it’s ceramic strength, paint color consistency, or mineral processing efficiency. High-quality ball mills are also more durable and require less maintenance, resulting in improved production uptime and reduced operational costs.