In the fast-paced world of quarrying and mining, technological advancements have played a pivotal role in transforming traditional practices and boosting efficiency. One such game-changing innovation is the modern cone crusher, which has redefined how quarries process and produce aggregates. This article delves into the hot-selling cone crusher technology that is revolutionizing the quarry industry, highlighting its benefits, features, and the impact it has on quarry operations.

The Evolution of Cone Crusher Technology:

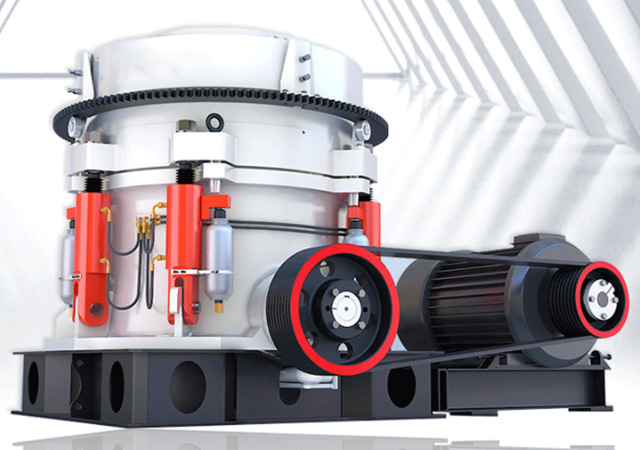

Cone crushers have come a long way since their inception, evolving from basic designs to complex machines capable of finely crushing various types of materials. The incorporation of advanced engineering concepts and state-of-the-art components has led to the development of high-performance cone crushers that outperform their predecessors in terms of efficiency, reliability, and versatility.

Key Features and Advantages:

Crushing Efficiency: Modern cone crushers are equipped with advanced hydraulic systems, adjustable settings, and intelligent control systems that optimize the crushing process. This results in higher throughput rates, reduced energy consumption, and consistent product sizes.

Versatility in Applications: Hot-selling cone crushers are designed to handle a wide range of materials, from hard and abrasive to soft and friable. Their adaptability makes them suitable for various stages of quarrying operations, including primary, secondary, and tertiary crushing.

Reduced Downtime: Cone crushers are built with durability in mind, incorporating wear-resistant materials and robust construction. This enhances their lifespan and reduces maintenance downtime, contributing to increased operational efficiency.

Automation and Remote Monitoring: Advanced cone crushers can be integrated with automation systems and remote monitoring technologies, allowing operators to optimize crusher performance, track production metrics, and diagnose issues in real-time.

Improved Particle Shape: The efficient crushing action of modern cone crushers produces well-shaped, cubical end products, which are highly desirable in the construction and concrete industries.

Environmental Considerations:

Hot-selling cone crusher technology isn’t just about improved efficiency; it also aligns with environmental sustainability. Many modern cone crushers are designed to be more eco-friendly by incorporating features like reduced noise levels, lower dust emissions, and improved energy efficiency. These factors not only benefit the environment but also contribute to a safer and more comfortable working environment for quarry personnel.

Case Studies: Real-World Impact

Several quarries around the world have already adopted hot-selling cone crusher technology, witnessing significant improvements in their operations. These case studies highlight how these innovative crushers have led to increased production, cost savings, and overall operational excellence.

Conclusion:

The introduction of hot-selling cone crusher technology has propelled the quarrying industry into a new era of productivity and sustainability. With enhanced crushing efficiency, versatile applications, and reduced environmental impact, these advanced crushers are reshaping the way quarries process aggregates. As quarry operators embrace this cutting-edge technology, they position themselves to thrive in a competitive market while contributing to a more responsible and efficient industry landscape.