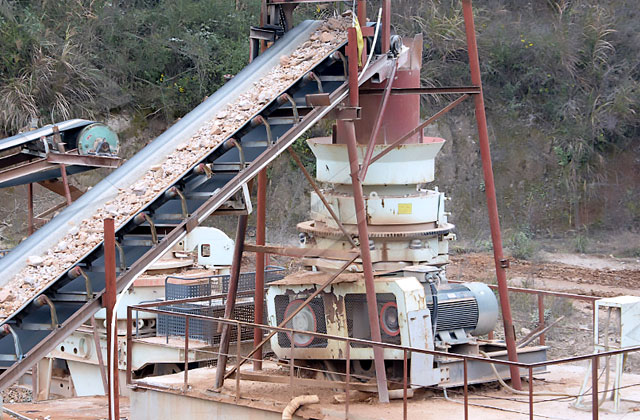

Quarry aggregate cone crushers are indispensable pieces of equipment in the mining and construction industry. These machines play a crucial role in processing raw materials extracted from quarries, turning them into valuable aggregates for various applications. If you are in the market for a quarry aggregate cone crusher, this guide will provide you with essential information to make an informed decision.

Understanding Quarry Aggregate Cone Crushers

Quarry aggregate cone crushers are heavy-duty machines designed to crush and process large rocks and raw materials into smaller, more manageable pieces. They are widely used in the construction and mining industries to produce materials like crushed stone, sand, gravel, and more. These crushers operate by compressing the material between a concave and a mantle, creating the desired aggregate size.

Key Features and Benefits

- Versatility: Quarry aggregate cone crushers are versatile and can handle a wide range of materials, from soft limestone to hard granite. This versatility makes them suitable for various applications, including road construction, building projects, and mining operations.

- High Crushing Efficiency: These machines offer high crushing efficiency, ensuring that the input materials are processed quickly and effectively. This leads to increased productivity and reduced operational costs.

- Adjustable Settings: Most cone crushers come with adjustable settings that allow you to control the final product size. This adaptability ensures that you can produce aggregates with the precise specifications required for your projects.

- Durability: Quarry aggregate cone crushers are built to withstand the rigors of heavy-duty operations. Their robust construction and high-quality materials ensure a long service life even in harsh working conditions.

- Low Maintenance: While regular maintenance is essential, modern cone crushers are designed for easy upkeep. This reduces downtime and maintenance costs, contributing to the overall efficiency of your operations.

Choosing the Right Cone Crusher

When selecting a quarry aggregate cone crusher for your specific needs, consider the following factors:

- Capacity: Determine the required production capacity of your crusher to ensure it can handle the volume of materials in your quarry.

- Material Hardness: Different cone crushers are designed to handle various material hardness levels. Make sure the one you choose is suited to your quarry’s materials.

- Crushing Chamber Configuration: Cone crushers come in different configurations, such as standard, short head, and fine. Choose the one that best fits your application.

- Power and Efficiency: Consider the power source and energy efficiency of the cone crusher to optimize your operational costs.

- Maintenance and Service: Check the manufacturer’s reputation for service and support, as this will be crucial to keeping your equipment running smoothly.

Quarry aggregate cone crushers are essential tools for the mining and construction industry, enabling the processing of raw materials into valuable aggregates. When searching for a cone crusher for sale, ensure you assess your specific needs, the crusher’s capacity and capabilities, and the manufacturer’s reputation for quality and service. Making an informed decision in this regard will ultimately lead to increased productivity and the success of your quarry or construction project.