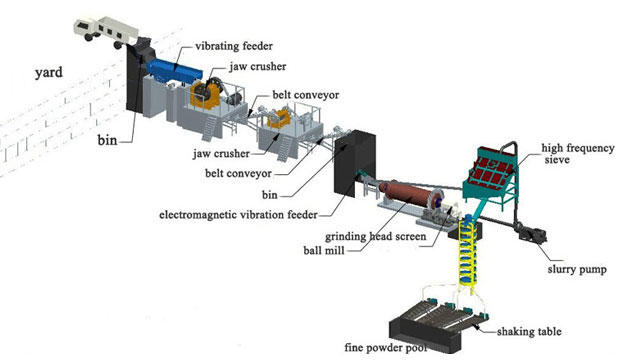

Manganese ore processing mainly includes three processes: crushing, grinding and beneficiation. The existing manganese ore processing process is no longer a single piece of equipment, but a complete production line composed of multiple pieces of equipment.

Manganese ore crushing equipment

The commonly used crushing equipment for manganese ore processing is the configuration of jaw crusher + cone crusher. It is more targeted, the wear resistance of the equipment is high, and the friction between each component during the working process is small, so the service life of the equipment is long, and it is also suitable for processing high-hardness manganese ore. The secondary crushing equipment is a cone crusher. The crushing principle of lamination is mainly the mutual extrusion of materials. Therefore, the wear and tear of the equipment itself is small, and the crushing particle size of the equipment is strong. The operation of the equipment is stable and simple to operate. The output quality is also relatively good.

Manganese ore grinding equipment

The manganese ore from the cone crusher needs to be ground by a ball mill. Compared with similar equipment, the energy consumption of the ball mill is about 50% lower under the same output. It is an energy-saving and environmentally friendly equipment, and the failure rate is low. longer.

Manganese ore beneficiation equipment

Manganese ore beneficiation equipment has a relatively high degree of automation and is more convenient to operate. The manganese ore powder that meets the beneficiation requirements is sent to a magnetic separator for strong magnetic separation to remove impurities, and the obtained manganese ore powder is sent to a dryer for drying to obtain manganese concentrate.