Cement grinding is the final process of cement manufacturing. Its main function is to grind cement clinker (and retarder, performance adjusting material, etc.) to a suitable particle size (represented by fineness, specific surface area, etc.) to form certain particles. Gradation, increase its hydration area, accelerate the hydration rate, and meet the requirements of cement paste coagulation and hardening. The production process of cement The cement … Read More →

Slag processing micro powder vertical mill

Slag grinding is an important part of slag powder processing. As the core equipment in the production process of slag grinding, Liming Heavy Industry’s slag processing micro powder vertical mill integrates fine crushing, grinding, drying, powder selection and conveying. The system is simple and compact in layout; low energy consumption, saving 30% to 40% of energy consumption compared with the ball mill system. Product advantages … Read More →

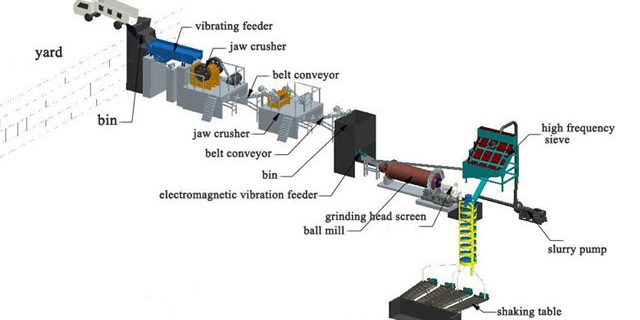

Iron ore processing equipment

Iron ore processing equipment includes crushing equipment, grinding equipment and selection equipment. Due to the differences in the properties of the ore, the equipment used is not exactly the same. The iron ore is evenly sent to the jaw crusher by the vibrating feeder for crushing, and the crushed material is transported to the vibrating screen for screening. The ore that has been screened to … Read More →

Copper ore processing equipment

The copper ore processing equipment mainly includes three processes: crushing, grinding and beneficiation. In the crushing process, the three-stage closed-circuit crushing is the most modern method suitable for high-hardness copper ore crushing, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding efficiency; The efficient grinding process can make the copper ore grind more fully; in the beneficiation process, … Read More →

Construction waste mobile crusher

The mobile construction waste crusher adopts advanced technology to integrate transportation, crushing, sand making and screening. It is a new type of building material that meets the quality inspection specifications. The integrated design of the unit, reasonable collocation, diversified configuration, meet the different needs of users, high-quality wearing parts material, increase the service life, strong mobility, and intelligent operation and production are safer. working principle … Read More →

Raymond mill requirements for materials

Raymond mill is suitable for processing limestone, marble, bentonite, kaolin, calcite, quartz stone, putty powder and other materials. During the working process, there are certain requirements for the moisture, hardness and particle size of the material, only within its appropriate range. Grinding can ensure the working efficiency of the Raymond mill. The humidity of the material by the Raymond mill: the humidity of the material … Read More →

Manganese ore processing equipment

Manganese ore processing mainly includes three processes: crushing, grinding and beneficiation. The existing manganese ore processing process is no longer a single piece of equipment, but a complete production line composed of multiple pieces of equipment. Manganese ore crushing equipmentThe commonly used crushing equipment for manganese ore processing is the configuration of jaw crusher + cone crusher. It is more targeted, the wear resistance of … Read More →

limestone aggregate crushing plant

The limestone aggregate crushing plant is a special aggregate processing production line for crushing limestone, limestone and other hardness minerals. It can coarsely or finely crush limestone into various sizes of stones that meet production requirements. Conducive to the later deep processing of limestone. The limestone aggregate crushing plant has become a common raw material crushing project in cement plants and stone plants. In the … Read More →

Cone crusher discharge efficiency

Cone crushers are divided into single-cylinder cone crushers and multi-cylinder cone crushers. The cone crusher adopts the lamination crushing method, and it is the key to improve the efficiency of the cone crusher, reduce the energy consumption, and increase the market competitiveness. Feed particle size of cone crusherFor cone crushers, different types or models can process different feed sizes. If the feed size is not … Read More →

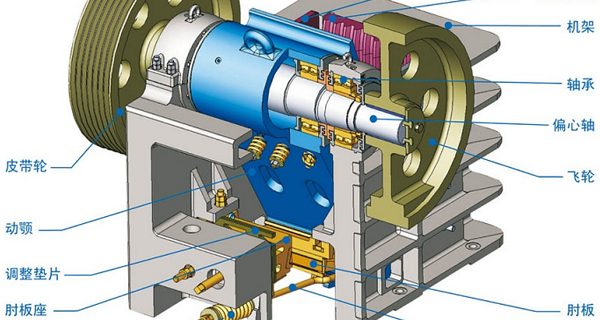

Jaw Crusher Parts Maintenance

Because the thrust plate of the jaw crusher is made of cast iron, and the thrust plate seat is mostly steel casting or variant cast iron, the thrust plate plays the role of transmitting motion and force, and also plays a role in safety protection and adjustment of the size of the ore discharge. . Because the thrust plate is installed at the lower part … Read More →